珀金斯403F-15T、404F-22、404F-22T柴油機維修操作保養一

詳細描述

Operation and

Maintenance

Manual

403F-15T, 404F-22 and 404F-22T

Industrial Engines

EL (Engine)

EN (Engine)

EP (Engine)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

Important Safety Information

Most accidents tha t involve produc t op eration, ma intena nc e and repair are caus ed by failure to

ob serve basic safety rules or precautions . An accident can often be avoided by recog nizing pote ntially

ha za rdous situations before an accident oc curs . A person mus t be alert to pote ntial ha za rds. This

person should also ha ve the ne cessary training, skills and tools to perform the se func tions properly.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and

could result in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you have

read and understood the operation, lubrication, maintenance and repair information.

Sa fety precautions and warning s are provided in this ma nua l and on the produc t. If the se ha za rd

warning s are not he eded, bod ily injury or death could oc cur to you or to othe r persons .

The ha za rds are identified by the “Safety Alert Symb ol” and followed by a “Signa l Word” suc h as

“DANGER”, “WARNING” or “CAUTION”. The Sa fety Alert “WARNING” label is shown below.

The me aning of this safety alert symb ol is as follows:

Attention! Become Alert! Your Safety is Involved.

The me ssage tha t appears und er the warning explains the ha za rd and can be either written or

pictorially presente d.

Op erations tha t ma y caus e produc t dama ge are identified by “NOTICE” labels on the produc t and in

this pub lication.

Perkins cannot anticipate every possible circumstance that might involve a potential hazard. The

warnings in this publication and on the product are, therefore, not all inclusive. If a tool, procedure,

work method or operating technique that is not specifically recommended by Perkins is used,

you must satisfy yourself that it is safe for you and for others. You should also ensure that the

product will not be damaged or be made unsafe by the operation, lubrication, maintenance or

repair procedures that you choose.

The informa tion, specifications , and illustrations in this pub lication are on the basis of informa tion tha t

was available at the time tha t the pub lication was written. The specifications , torque s, pressure s,

me asure me nts , adjustme nts , illustrations , and othe r items can cha ng e at any time. These cha ng es can

affect the service tha t is given to the produc t. Ob tain the comp lete and mos t current informa tion before

you start any job. Pe rkins dealers or Pe rkins distributors ha ve the mos t current informa tion available.

When replacement parts are required for this

product Perkins recommends using Perkins

replacement parts.

Failure to heed this warning can lead to prema-

ture failures, product damage, personal injury or

death.

This document is printed from SPI². Not for RESALE

![]()

![]()

SEBU8609

3

Table of Contents

Table of Contents

Refill Capacities....................... ....................... 57

Maintenance Recommendations.......... .......... 70

Maintenance Interval Schedule........... ........... 73

Warranty Section

Foreword.............................. ............................. 4

Safety Section

Safety Messages....................... ....................... 5

General Hazard Information............... .............. 5

Burn Prevention........................ ........................ 9

Fire Prevention and Explosion Prevention ... .. 10

Crushing Prevention and Cutting Prevention . .11

Mounting and Dismounting............... .............. 12

Before Starting Engine ................. .................. 12

Engine Starting........................ ....................... 12

Engine Stopping....................... ...................... 13

Electrical System...................... ...................... 13

Engine Electronics..................... ..................... 14

Product Information Section

Warranty Information................... ................... 99

Reference Information Section

Reference Materials .................. ................... 103

Index Section

Index............................... .............................. 104

General Information.................... .................... 15

Product Identification Information.......... ......... 26

Operation Section

Lifting and Storage..................... ..................... 28

Features and Controls.................. .................. 30

Engine Diagnostics..................... .................... 43

Engine Starting........................ ....................... 45

Engine Operation...................... ...................... 48

Cold Weather Operation................. ................ 52

Engine Stopping....................... ...................... 56

Maintenance Section

This document is printed from SPI². Not for RESALE

![]()

4

SEBU8609

Foreword

Foreword

Recommended service should be performed at the

appropriate intervals as indicated in the Maintenance

Interval Schedule. The actual operating environment

of the engine also governs the Maintenance Interval

Schedule. Therefore, under extremely severe, dusty,

wet or freezing cold operating conditions, more

frequent lubrication and maintenance than is

specified in the Maintenance Interval Schedule may

be necessary.

Literature Information

This manual contains safety, operation instructions,

lubrication and maintenance information. This manual

should be stored in or near the engine area in a

literature holder or literature storage area. Read,

study and keep it with the literature and engine

information.

The maintenance schedule items are organized for a

preventive maintenance management program. If the

preventive maintenance program is followed, a

periodic tune-up is not required. The implementation

of a preventive maintenance management program

should minimize operating costs through cost

avoidances resulting from reductions in unscheduled

downtime and failures.

English is the primary language for all Perkins

publications. The English used facilitates translation

and consistency.

Some photographs or illustrations in this manual

show details or attachments that may be different

from your engine. Guards and covers may have been

removed for illustrative purposes. Continuing

improvement and advancement of product design

may have caused changes to your engine which are

not included in this manual. Whenever a question

arises regarding your engine, or this manual, please

consult with your Perkins dealer or your Perkins

distributor for the latest available information.

Maintenance Intervals

Perform maintenance on items at multiples of the

original requirement. We recommend that the

maintenance schedules be reproduced and displayed

near the engine as a convenient reminder. We also

recommend that a maintenance record be maintained

as part of the engine's permanent record.

Safety

Your authorized Perkins dealer or your Perkins

distributor can assist you in adjusting your

maintenance schedule to meet the needs of your

operating environment.

This safety section lists basic safety precautions. In

addition, this section identifies hazardous, warning

situations. Read and understand the basic

precautions listed in the safety section before

operating or performing lubrication, maintenance and

repair on this product.

Overhaul

Major engine overhaul details are not covered in the

Operation and Maintenance Manual except for the

interval and the maintenance items in that interval.

Major repairs should only be carried out by Perkins

authorized personnel. Your Perkins dealer or your

Perkins distributor offers a variety of options

regarding overhaul programs. If you experience a

major engine failure, there are also numerous after

failure overhaul options available. Consult with your

Perkins dealer or your Perkins distributor for

information regarding these options.

Operation

Operating techniques outlined in this manual are

basic. They assist with developing the skills and

techniques required to operate the engine more

efficiently and economically. Skill and techniques

develop as the operator gains knowledge of the

engine and its capabilities.

The operation section is a reference for operators.

Photographs and illustrations guide the operator

through procedures of inspecting, starting, operating

and stopping the engine. This section also includes a

discussion of electronic diagnostic information.

California Proposition 65 Warning

Diesel engine exhaust and some of its constituents

are known to the State of California to cause cancer,

birth defects, and other reproductive harm. Battery

posts, terminals and related accessories contain lead

and lead compounds. Wash hands after handling.

Maintenance

The maintenance section is a guide to engine care.

The illustrated, step-by-step instructions are grouped

by service hours and/or calendar time maintenance

intervals. Items in the maintenance schedule are

referenced to detailed instructions that follow.

This document is printed from SPI². Not for RESALE

![]()

SEBU8609

5

Safety Section

Safety Messages

Safety Section

Do not operate or work on this equipment unless

you have read and understand the instructions

and warnings in the Operation and Maintenance

Manuals. Failure to follow the instructions or heed

the warnings could result in serious injury or

death.

i05139549

Safety Messages

There may be several specific warning signs on your

engine. The exact location and a description of the

warning signs are reviewed in this section. Become

familiar with all warning signs.

Ensure that all of the warning signs are legible. Clean

the warning signs or replace the warning signs if the

words cannot be read or if the illustrations are not

visible. Use a cloth, water, and soap to clean the

warning signs. Do not use solvents, gasoline, or other

harsh chemicals. Solvents, gasoline, or harsh

chemicals could loosen the adhesive that secures the

warning signs. The warning signs that are loosened

could drop off the engine.

Replace any warning sign that is damaged or

missing. If a warning sign is attached to a part of the

engine that is replaced, install a new warning sign on

the replacement part. Your Perkins dealer or your

distributor can provide new warning signs.

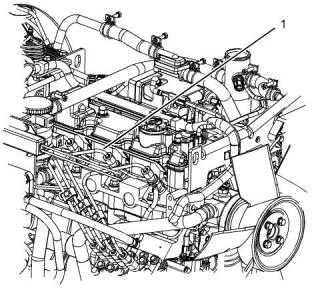

Illustration 2

g01154807

Typical example

(1) Universal Warning

The location of the universal warning label is located

on the right side of the valve mechanism cover.

i05139571

General Hazard Information

Illustration 1

g03256898

Illustration 3

g00104545

(1) Universal Warning

Attach a “Do Not Operate” warning tag or a similar

warning tag to the start switch or to the controls

before you service the equipment or before you repair

the equipment.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

6

SEBU8609

Safety Section

General Hazard Information

• Tampering with the engine installation or tampering

with the OEM supplied wiring can be dangerous.

Personal injury, death and/or engine damage

could result.

• The engine is stopped. Ensure that the engine

cannot be started.

• The protective locks or the controls are in the

applied position.

• Vent the engine exhaust to the outside when the

engine is operated in an enclosed area.

• Engage the secondary brakes or parking brakes.

• Block the vehicle or restrain the vehicle before

maintenance or repairs are performed.

• If the engine is not running, do not release the

secondary brake or the parking brake systems

unless the vehicle is blocked or unless the vehicle

is restrained.

• Disconnect the batteries when maintenance is

performed or when the electrical system is

serviced. Disconnect the battery ground leads.

Tape the leads in order to help prevent sparks.

• Wear a hard hat, protective glasses, and other

protective equipment, as required.

• Do not attempt any repairs or any adjustments to

the engine while the engine is operating.

• When work is performed around an engine that is

operating, wear protective devices for ears in order

to help prevent damage to hearing.

• Do not attempt any repairs that are not

understood. Use the proper tools. Replace any

equipment that is damaged or repair the

equipment.

• Do not wear loose clothing or jewelry that can snag

on controls or on other parts of the engine.

• Ensure that all protective guards and all covers are

secured in place on the engine.

• For initial start-up of a new engine or for starting an

engine that has been serviced, make provisions to

stop the engine if an overspeed occurs. The

stopping of the engine may be accomplished by

shutting off the fuel supply and/or the air supply to

the engine. Ensure that only the fuel supply line is

shut off. Ensure that the fuel return line is open.

• Never put maintenance fluids into glass

containers. Glass containers can break.

• Use all cleaning solutions with care.

• Report all necessary repairs.

• Start the engine from the operators station (cab).

Never short across the starting motor terminals or

the batteries. This action could bypass the engine

neutral start system and/or the electrical system

could be damaged.

Unless other instructions are provided, perform the

maintenance under the following conditions:

Illustration 4

g00702020

Wear a hard hat, protective glasses, and other

protective equipment, as required.

Do not wear loose clothing or jewelry that can snag

on controls or on other parts of the engine.

Make sure that all protective guards and all covers

are secured in place on the engine.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

SEBU8609

7

Safety Section

General Hazard Information

Keep the engine free from foreign material. Remove

debris, oil, tools, and other items from the deck, from

walkways, and from steps.

Never put maintenance fluids into glass containers.

Drain all liquids into a suitable container.

Obey all local regulations for the disposal of liquids.

Use all cleaning solutions with care.

Report all necessary repairs.

Do not allow unauthorized personnel on the

equipment.

Ensure that the power supply is disconnected before

you work on the bus bar or the glow plugs.

Illustration 5

g00687600

Perform maintenance on the engine with the

equipment in the servicing position. Refer to the OEM

information for the procedure for placing the

equipment in the servicing position.

Always use a board or cardboard when you check for

a leak. Leaking fluid that is under pressure can

penetrate body tissue. Fluid penetration can cause

serious injury and possible death. A pin hole leak can

cause severe injury. If fluid is injected into your skin,

you must get treatment immediately. Seek treatment

from a doctor that is familiar with this type of injury.

Pressure Air and Water

Pressurized air and/or water can cause debris and/or

hot water to be blown out. This could result in

personal injury.

Containing Fluid Spillage

Care must be taken in order to ensure that fluids are

contained during performance of inspection,

maintenance, testing, adjusting, and repair of the

engine. Make provision to collect the fluid with a

suitable container before any compartment is opened

or before any component is disassembled.

The direct application of pressurized air or

pressurized water to the body could result in personal

injury.

When pressurized air and/or water is used for

cleaning, wear protective clothing, protective shoes,

and eye protection. Eye protection includes goggles

or a protective face shield.

• Only use the tools that are suitable for collecting

fluids and equipment that is suitable for collecting

fluids.

The maximum air pressure for cleaning purposes

must be below 205 kPa (30 psi). The maximum water

pressure for cleaning purposes must be below

275 kPa (40 psi).

• Only use the tools that are suitable for containing

fluids and equipment that is suitable for containing

fluids.

Fluid Penetration

Obey all local regulations for the disposal of liquids.

Pressure can be trapped in the hydraulic circuit long

after the engine has been stopped. The pressure can

cause hydraulic fluid or items such as pipe plugs to

escape rapidly if the pressure is not relieved correctly.

Do not remove any hydraulic components or parts

until pressure has been relieved or personal injury

may occur. Do not disassemble any hydraulic

components or parts until pressure has been relieved

or personal injury may occur. Refer to the OEM

information for any procedures that are required to

relieve the hydraulic pressure.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

8

SEBU8609

Safety Section

General Hazard Information

Inhalation

• Never use compressed air for cleaning.

• Avoid brushing materials that contain asbestos.

• Avoid grinding materials that contain asbestos.

• Use a wet method in order to clean up asbestos

materials.

• A vacuum cleaner that is equipped with a high

efficiency particulate air filter (HEPA) can also be

used.

• Use exhaust ventilation on permanent machining

jobs.

• Wear an approved respirator if there is no other

way to control the dust.

Illustration 6

g00702022

• Comply with applicable rules and regulations for

the work place. In the United States , use

Occupational Safety and Health Administration

(OSHA) requirements. These OSHA

Exhaust

Use caution. Exhaust fumes can be hazardous to

health. If you operate the equipment in an enclosed

area, adequate ventilation is necessary.

requirements can be found in 29 CFR 1910.1001.

• Obey environmental regulations for the disposal of

asbestos.

Asbestos Information

• Stay away from areas that might have asbestos

particles in the air.

Perkins equipment and replacement parts that are

shipped from Perkins are asbestos free. Perkins

recommends the use of only genuine Perkins

replacement parts. Use the following guidelines when

you handle any replacement parts that contain

asbestos or when you handle asbestos debris.

Dispose of Waste Properly

Use caution. Avoid inhaling dust that might be

generated when you handle components that contain

asbestos fibers. Inhaling this dust can be hazardous

to your health. The components that may contain

asbestos fibers are brake pads, brake bands, lining

material, clutch plates, and some gaskets. The

asbestos that is used in these components is usually

bound in a resin or sealed in some way. Normal

handling is not hazardous unless airborne dust that

contains asbestos is generated.

If dust that may contain asbestos is present, there are

several guidelines that should be followed:

Illustration 7

g00706404

Improperly disposing of waste can threaten the

environment. Potentially harmful fluids should be

disposed of according to local regulations.

Always use leakproof containers when you drain

fluids. Do not pour waste onto the ground, down a

drain, or into any source of water.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

SEBU8609

9

Safety Section

Burn Prevention

i05200861

Coolant

Burn Prevention

When the engine is at operating temperature, the

engine coolant is hot. The coolant is also under

pressure. The radiator and all lines to the heaters or

to the engine contain hot coolant.

Do not touch any part of an operating engine system.

The engine, the exhaust, and the engine

aftertreatmentsystem can reach temperatures as

high as 650 °C (1202 °F) under normal operating

conditions.

Any contact with hot coolant or with steam can cause

severe burns. Allow cooling system components to

cool before the cooling system is drained.

Check that the coolant level after the engine has

stopped and the engine has been allowed to cool.

At idle engine speed and/or zero vehicle speed, an

operator can request a manual regeneration. Under

this condition, the exhaust gas temperature can reach

650 °C (1202 °F). Otherwise automatic regeneration

can produce exhaust gas temperatures as high as

650 °C (1202 °F).

Ensure that the filler cap is cool before removing the

filler cap. The filler cap must be cool enough to touch

with a bare hand. Remove the filler cap slowly in

order to relieve pressure.

Cooling system conditioner contains alkali. Alkali can

cause personal injury. Do not allow alkali to contact

the skin, the eyes, or the mouth.

Allow the engine system to cool before any

maintenance is performed. Relieve all pressure in the

following systems, hydraulic system, lubrication

system, fuel system, and the cooling system before

related items are disconnected.

Oils

Hot oil and hot lubricating components can cause

personal injury. Do not allow hot oil to contact the

skin. Also, do not allow hot components to contact the

skin.

Contact with high pressure fuel may cause fluid

penetration and burn hazards. High pressure fuel

spray may cause a fire hazard. Failure to follow

these inspection, maintenance and service in-

structions may cause personal injury or death.

Batteries

Electrolyte is an acid. Electrolyte can cause personal

injury. Do not allow electrolyte to contact the skin or

the eyes. Always wear protective glasses for

servicing batteries. Wash hands after touching the

batteries and connectors. Use of gloves is

recommended.

After the engine has stopped, allow if active the

regeneration active lamp to be extinguished before

any service or repair is performed.

Induction System

Sulfuric Acid Burn Hazard may cause serious per-

sonal injury or death.

The exhaust gas cooler may contain a small

amount of sulfuric acid. The use of fuel with sulfur

levels greater than 15 ppm may increase the

amount of sulfuric acid formed. The sulfuric acid

may spill from the cooler during service of the en-

gine. The sulfuric acid will burn the eyes, skin and

clothing on contact. Always wear the appropriate

personal protective equipment (PPE) that is noted

on a material safety data sheet (MSDS) for sulfuric

acid. Always follow the directions for first aid that

are noted on a material safety data sheet (MSDS)

for sulfuric acid.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

10

SEBU8609

Safety Section

Fire Prevention and Explosion Prevention

i04047444

Do not weld on lines or tanks that contain flammable

fluids. Do not flame cut lines or tanks that contain

flammable fluid. Clean any such lines or tanks

thoroughly with a nonflammable solvent prior to

welding or flame cutting.

Fire Prevention and Explosion

Prevention

Wiring must be kept in good condition. Ensure that all

electrical wires are correctly routed and securely

attached. Check all electrical wires daily. Repair any

wires that are loose or frayed before you operate the

engine. Clean all electrical connections and tighten all

electrical connections.

Eliminate all wiring that is unattached or unnecessary.

Do not use any wires or cables that are smaller than

the recommended gauge. Do not bypass any fuses

and/or circuit breakers.

Arcing or sparking could cause a fire. Secure

connections, recommended wiring, and correctly

maintained battery cables will help to prevent arcing

or sparking.

Ensure that the engine is stopped. Inspect all lines

and hoses for wear or for deterioration. The hoses

must be correctly routed. The lines and hoses must

have adequate support and secure clamps.

Illustration 8

g00704000

All fuels, most lubricants, and some coolant mixtures

are flammable.

Oil filters and fuel filters must be correctly installed.

The filter housings must be tightened to the correct

torque. Refer to the Disassembly and Assembly

manual for more information.

Flammable fluids that are leaking or spilled onto hot

surfaces or onto electrical components can cause a

fire. Fire may cause personal injury and property

damage.

After the emergency stop button has been operated,

ensure that you allow 15 minutes, before the engine

covers are removed.

Determine whether the engine will be operated in an

environment that allows combustible gases to be

drawn into the air inlet system. These gases could

cause the engine to overspeed. Personal injury,

property damage, or engine damage could result.

If the application involves the presence of

combustible gases, consult your Perkins dealer and/

or your Perkins distributor for additional information

about suitable protection devices.

Remove all flammable combustible materials or

conductive materials such as fuel, oil, and debris from

the engine. Do not allow any flammable combustible

materials or conductive materials to accumulate on

the engine.

Store fuels and lubricants in correctly marked

containers away from unauthorized persons. Store

oily rags and any flammable materials in protective

containers. Do not smoke in areas that are used for

storing flammable materials.

Illustration 9

g00704059

Use caution when you are refueling an engine. Do not

smoke while you are refueling an engine. Do not

refuel an engine near open flames or sparks. Always

stop the engine before refueling.

Do not expose the engine to any flame.

Exhaust shields (if equipped) protect hot exhaust

components from oil or fuel spray in case of a line, a

tube, or a seal failure. Exhaust shields must be

installed correctly.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

SEBU8609

11

Safety Section

Crushing Prevention and Cutting Prevention

• High-pressure fuel line or lines are removed.

• End fittings are damaged or leaking.

• Outer coverings are chafed or cut.

• Wires are exposed.

• Outer coverings are ballooning.

• Flexible parts of the hoses are kinked.

• Outer covers have embedded armoring.

• End fittings are displaced.

Make sure that all clamps, guards, and heat shields

are installed correctly. During engine operation,

correct installation will help to prevent vibration,

rubbing against other parts, and excessive heat.

Regeneration

The exhaust gas temperature during regeneration will

be elevated. Follow proper fire prevention instructions

and use the disable switch function when appropriate.

Illustration 10

g00704135

Gases from a battery can explode. Keep any open

flames or sparks away from the top of a battery. Do

not smoke in battery charging areas.

i02143194

Never check the battery charge by placing a metal

object across the terminal posts. Use a voltmeter or a

hydrometer.

Crushing Prevention and

Cutting Prevention

Incorrect jumper cable connections can cause an

explosion that can result in injury. Refer to the

Operation Section of this manual for specific

instructions.

Support the component correctly when work beneath

the component is performed.

Do not charge a frozen battery. Charge a frozen

battery may cause an explosion.

Unless other maintenance instructions are provided,

never attempt adjustments while the engine is

running.

The batteries must be kept clean. The covers (if

equipped) must be kept on the cells. Use the

recommended cables, connections, and battery box

covers when the engine is operated.

Stay clear of all rotating parts and of all moving parts.

Leave the guards in place until maintenance is

performed. After the maintenance is performed,

reinstall the guards.

Fire Extinguisher

Keep objects away from moving fan blades. The fan

blades will throw objects or cut objects.

Make sure that a fire extinguisher is available. Be

familiar with the operation of the fire extinguisher.

Inspect the fire extinguisher and service the fire

extinguisher regularly. Obey the recommendations on

the instruction plate.

When objects are struck, wear protective glasses in

order to avoid injury to the eyes.

Chips or other debris may fly off objects when objects

are struck. Before objects are struck, ensure that no

one will be injured by flying debris.

Lines, Tubes, and Hoses

Do not bend high-pressure lines. Do not strike high-

pressure lines. Do not install any lines that are

damaged.

Leaks can cause fires. Consult your Perkins dealer

or your Perkins distributor for replacement parts.

Replace the parts if any of the following conditions

are present:

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

12

SEBU8609

Safety Section

Mounting and Dismounting

i04016709

i02157354

Mounting and Dismounting

Engine Starting

Do not climb on the engine or the engine

aftertreatment.The engine and aftertreatment have

not been designed with mounting or dismounting

locations.

Do not use aerosol types of starting aids such as

ether. Such use could result in an explosion and

personal injury.

Refer to the OEM for the location of foot and hand

holds for your specific application.

If a warning tag is attached to the engine start switch

or to the controls, DO NOTstart the engine or move

the controls. Consult with the person that attached

the warning tag before the engine is started.

i02813489

Before Starting Engine

All protective guards and all protective covers must

be installed if the engine must be started in order to

perform service procedures. To help prevent an

accident that is caused by parts in rotation, work

around the parts carefully.

Before the initial start-up of an engine that is new,

serviced or repaired, make provision to shut the

engine off, in order to stop an overspeed. This may

be accomplished by shutting off the air and/or fuel

supply to the engine.

Start the engine from the operator's compartment or

from the engine start switch.

Overspeed shutdown should occur automatically for

engines that are controlled electronically. If automatic

shutdown does not occur, press the emergency stop

button in order to cut the fuel and/or air to the engine.

Always start the engine according to the procedure

that is described in the Operation and Maintenance

Manual, “Engine Starting” topic in the Operation

Section. Knowing the correct procedure will help to

prevent major damage to the engine components.

Knowing the procedure will also help to prevent

personal injury.

Inspect the engine for potential hazards.

Before starting the engine, ensure that no one is on,

underneath, or close to the engine. Ensure that the

area is free of personnel.

To ensure that the jacket water heater (if equipped)

and/or the lube oil heater (if equipped) is working

correctly, check the water temperature gauge and the

oil temperature gauge during the heater operation.

If equipped, ensure that the lighting system for the

engine is suitable for the conditions. Ensure that all

lights work correctly, if equipped.

All protective guards and all protective covers must

be installed if the engine must be started in order to

perform service procedures. To help prevent an

accident that is caused by parts in rotation, work

around the parts carefully.

Engine exhaust contains products of combustion

which can be harmful to your health. Always start the

engine and operate the engine in a well ventilated

area. If the engine is started in an enclosed area, vent

the engine exhaust to the outside.

Do not bypass the automatic shutoff circuits. Do not

disable the automatic shutoff circuits. The circuits are

provided in order to help prevent personal injury. The

circuits are also provided in order to help prevent

engine damage.

Note: The engine is equipped with an automatic

device for cold starting for normal conditions of

operation. If the engine will be operated in very cold

conditions, then an extra cold starting aid may be

required. Normally, the engine will be equipped with

the correct type of starting aid for your region of

operation.

See the Service Manual for repairs and for

adjustments.

The 400 Series engines are equipped with a glow

plug starting aid in each individual cylinder that heats

the intake air in order to improve starting.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

SEBU8609

13

Safety Section

Engine Stopping

i02234873

Grounding Practices

Engine Stopping

Stop the engine according to the procedure in the

Operation and Maintenance Manual, “Engine

Stopping (Operation Section)” in order to avoid

overheating of the engine and accelerated wear of

the engine components.

Use the Emergency Stop Button (if equipped) ONLY

in an emergency situation. Do not use the Emergency

Stop Button for normal engine stopping. After an

emergency stop, DO NOTstart the engine until the

problem that caused the emergency stop has been

corrected.

Stop the engine if an overspeed condition occurs

during the initial start-up of a new engine or an engine

that has been overhauled.

To stop an electronically controlled engine, cut the

power to the engine and/or shutting off the air supply

to the engine.

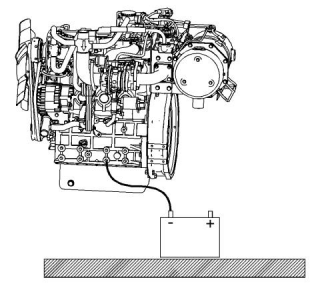

Illustration 11

g02324975

Typical example

Ground to battery

i04047709

Electrical System

Never disconnect any charging unit circuit or battery

circuit cable from the battery when the charging unit is

operating. A spark can cause the combustible gases

that are produced by some batteries to ignite.

To help prevent sparks from igniting combustible

gases that are produced by some batteries, the

negative “−” cable should be connected last from the

external power source to the primary position for

grounding.

Check the electrical wires daily for wires that are

loose or frayed. Tighten all loose electrical

connections before the engine is started. Repair all

frayed electrical wires before the engine is started.

See the Operation and Maintenance Manual for

specific starting instructions.

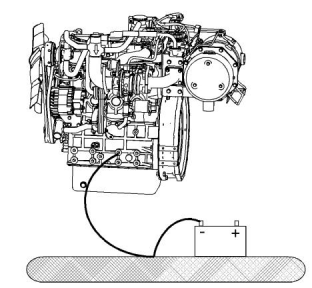

Illustration 12

g02324976

Typical example

Alternate ground to battery

Correct grounding for the engine electrical system is

necessary for optimum engine performance and

reliability. Incorrect grounding will result in

uncontrolled electrical circuit paths and in unreliable

electrical circuit paths.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

14

SEBU8609

Safety Section

Engine Electronics

Uncontrolled electrical circuit paths can result in

damage to the crankshaft bearing journal surfaces

and to aluminum components.

The Engine Monitoring package can vary for different

engine models and different engine applications.

However, the monitoring system and the engine

monitoring control will be similar for all engines.

Engines that are installed without engine-to-frame

ground straps can be damaged by electrical

discharge.

Note: Many of the engine control systems and

display modules that are available for Perkins

Engines will work in unison with the Engine

Monitoring System. Together, the two controls will

provide the engine monitoring function for the specific

engine application. Refer to the Troubleshooting for

more information on the Engine Monitoring System.

To ensure that the engine and the engine electrical

systems function correctly, an engine-to-frame

ground strap with a direct path to the battery must be

used. This path may be provided by way of a direct

engine ground to the frame.

The connections for the grounds should be tight and

free of corrosion. The engine alternator must be

grounded to the negative “-” battery terminal with a

wire that is adequate to handle the full charging

current of the alternator.

The power supply connections and the ground

connections for the engine electronics should always

be from the isolator to the battery.

i05181812

Engine Electronics

Tampering with the electronic system installation

or the OEM wiring installation can be dangerous

and could result in personal injury or death and/or

engine damage.

This engine has a comprehensive, programmable

Engine Monitoring System. The Electronic Control

Module (ECM) has the ability to monitor the engine

operating conditions. If any of the engine parameters

extend outside an allowable range, the ECM will

initiate an immediate action.

The following actions are available for engine

monitoring control:

• Warning

• Derate

• Shutdown

The following monitored engine operating conditions

and components have the ability to limit engine speed

and/or the engine power:

• Oil Pressure Switch

• Coolant Temperature Sensor

• Engine Aftertreatment System

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

SEBU8609

15

,,Product Information Section

Model View Illustrations

Product Information

Section

General Information

i05139695

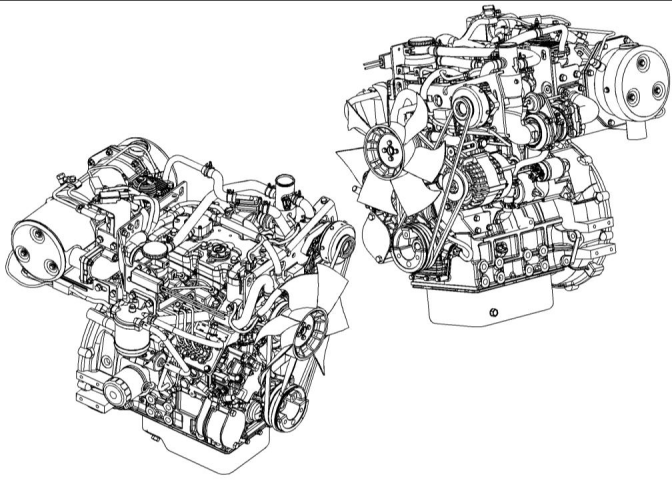

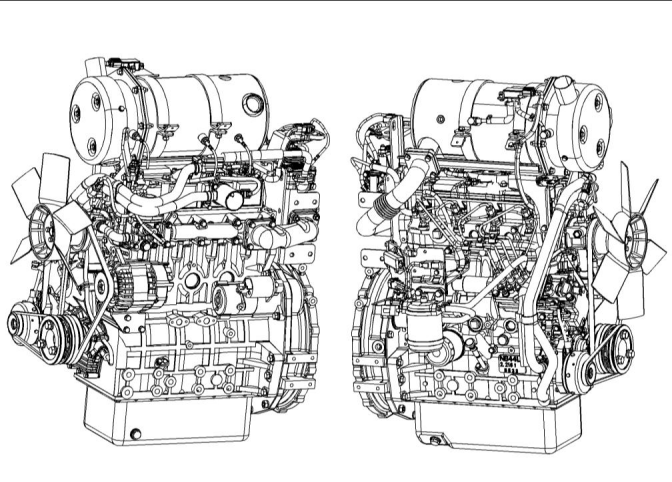

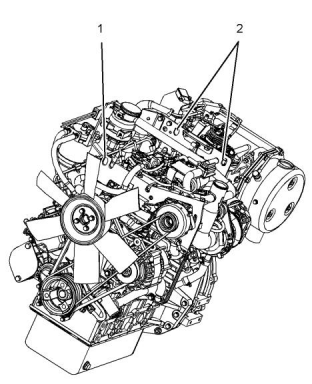

Model View Illustrations

(Engines and Aftertreatment)

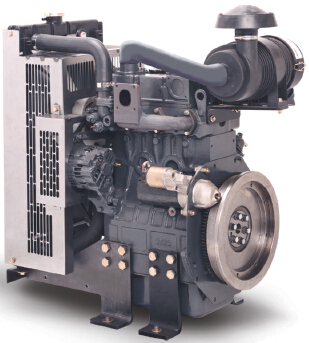

The following model views show typical features of

the engine. Due to individual applications, your

engine may appear different from the illustrations.

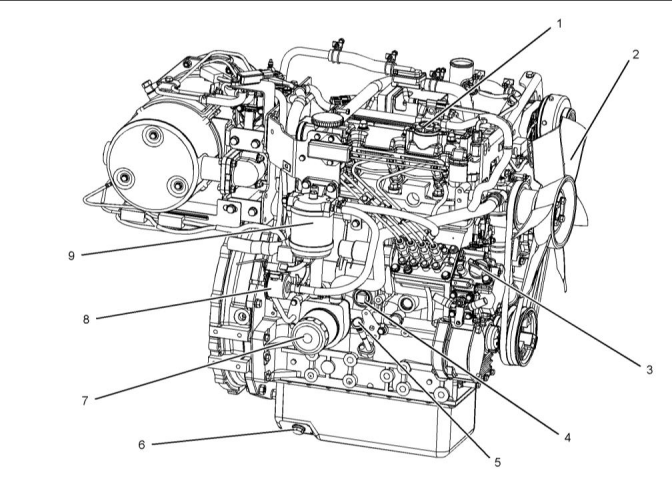

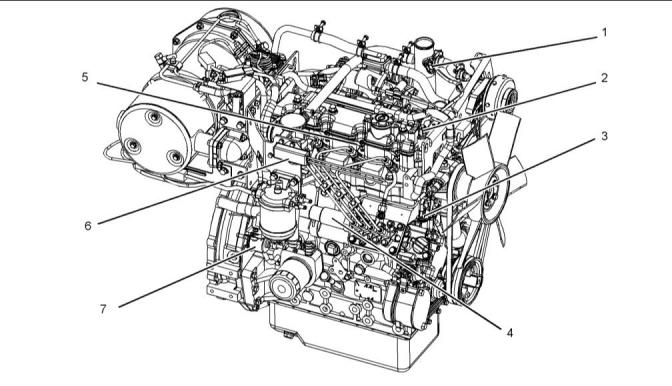

403F-15T

Illustration 13

g03246538

Typical example

This document is printed from SPI². Not for RESALE

![]()

![]()

16

SEBU8609

General Information

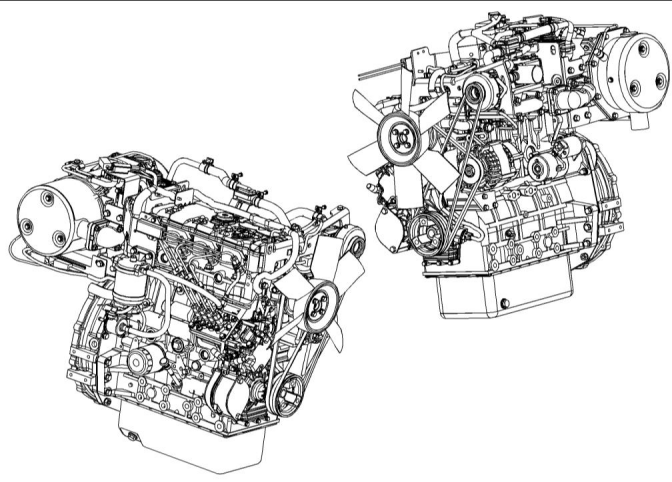

Model View Illustrations

404F-22

Illustration 14

g03246558

Typical example

This document is printed from SPI². Not for RESALE

![]()

![]()

SEBU8609

17

General Information

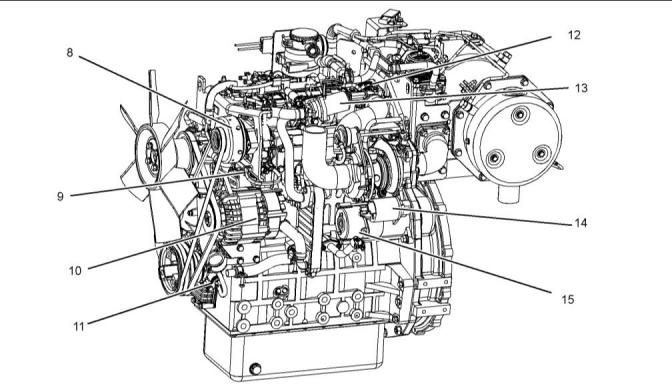

Model View Illustrations

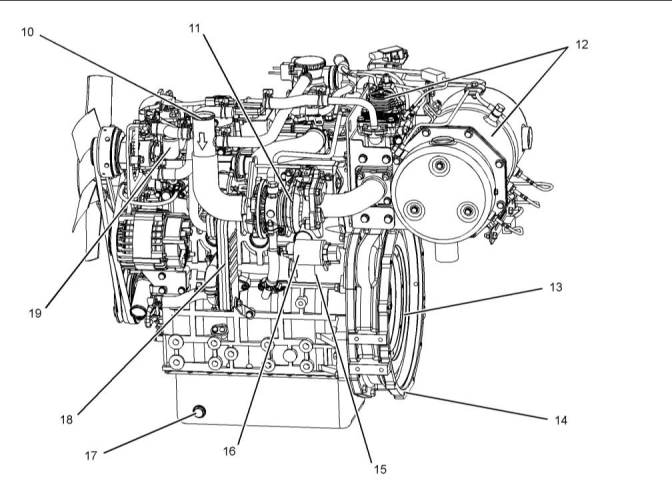

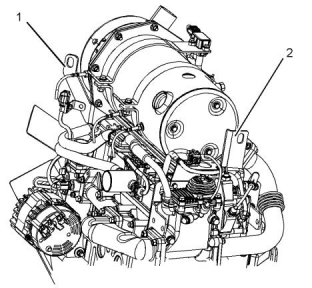

404F-22T

Illustration 15

g03246676

(1) Top oil filler

(2) Fan

(3) Side oil filler

(4) Cylinder block drain plug

(5) Oil gauge (Dipstick)

(6) Rear oil drain plug

(7) Oil filter

(8) Electric fuel pump

(9) Secondary fuel filter

This document is printed from SPI². Not for RESALE

![]()

![]()

18

SEBU8609

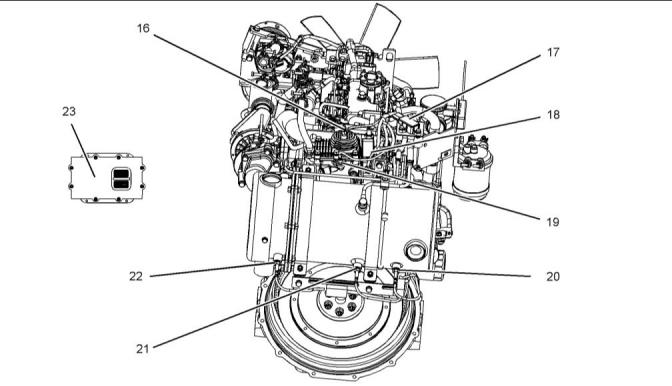

General Information

Model View Illustrations

Illustration 16

g03246563

(10) Air intake

(14) Flywheel housing

(15) Starting motor

(16) Solenoid for starting motor

(17) Front oil drain plug

(18) NOx reduction system cooler

(19) Coolant outlet

(11) Turbocharger

(12) Aftertreatment system

(13) Flywheel

This document is printed from SPI². Not for RESALE

![]()

![]()

SEBU8609

19

General Information

Model View Illustrations

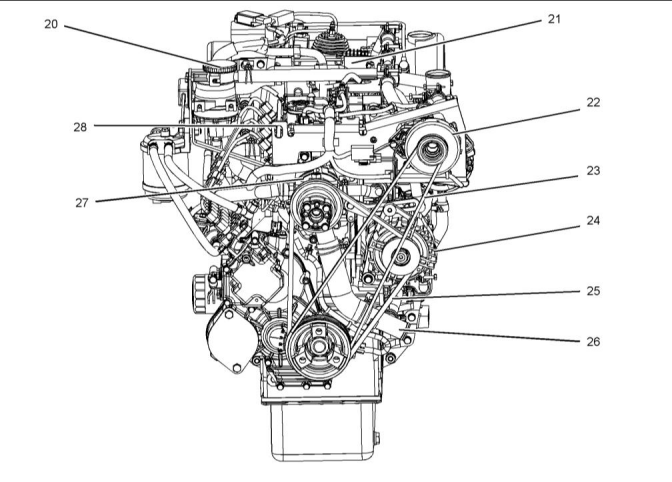

Illustration 17

g03249056

(20) Engine crankcase breather

(21) Rear lifting eye bracket

(22) Air pump

(23) Air pump drive belt

(24) Alternator

(25) Fan and alternator drive belt

(26) Coolant intake

(27) Water pump

(28) Front lifting eye

This document is printed from SPI². Not for RESALE

![]()

![]()

20

SEBU8609

General Information

Model View Illustrations

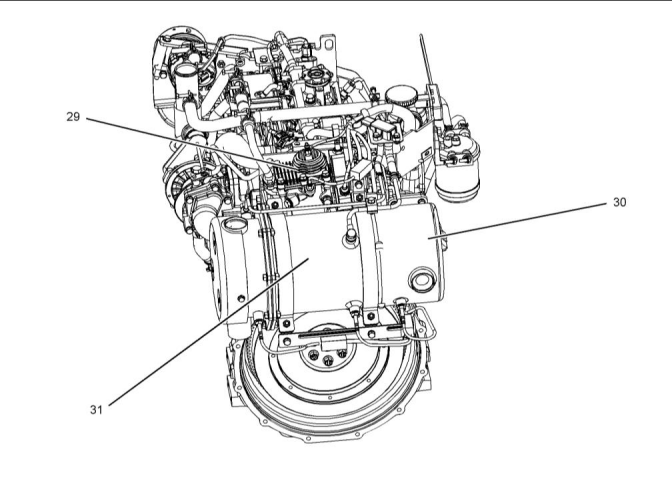

AftertreatmentSystem

Illustration 18

g03249241

(29) Aftertreatment Regeneration Device

(ARD), also known as the (Burner)

(30) Diesel Oxidation Catalyst (DOC)

(31) Diesel Particulate Filter (DPF)

This document is printed from SPI². Not for RESALE

![]()

![]()

SEBU8609

21

General Information

Model View Illustrations

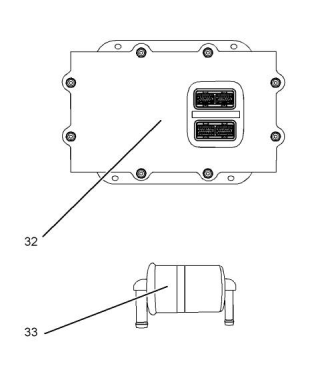

Off Engine Parts

Illustration 19

g03271819

(32) Electronic Control Unit (ECM)

(33) In line fuel filter

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

22

SEBU8609

General Information

Product Description

Engine with Low Mounted Air Pump

Illustration 20

g03321871

i05139813

The crankshaft for a three cylinder engine has four

main bearing journals. The crankshaft for a four

cylinder engine has five main bearing journals. End

play is controlled by the thrust washers that are

located on the rear main bearing.

Product Description

The 400F models are indirect injection engines. The

fuel injection pump is operated by a solenoid that is

controlled by a Pulse Width Modulation (PWM) signal

from the ECM.

The timing gears are stamped with timing marks in

order to ensure the correct assembly of the gears.

With the timing marks on the crankshaft gear

camshaft gear and the idler gear aligned No. 1 piston

will be at top center compression stroke.

The cylinder head assembly has one inlet valve and

one exhaust valve for each cylinder. Each cylinder

valve has a single valve spring.

The crankshaft gear turns the idler gear which then

turns the camshaft gear and the gear for the engine

oil pump.

The pistons have two compression rings and an oil

control ring. It is important to ensure the correct piston

height so that the piston does not contact the cylinder

head. The correct piston height also ensures efficient

combustion of fuel that is necessary in order to

conform to requirements for emissions.

The fuel injection pump is mounted in the cylinder

block. The fuel injection pump is operated by the

camshaft. The fuel pump is located on the right-hand

side of the cylinder block. The fuel pump is electrically

operated.

This document is printed from SPI². Not for RESALE

![]()

![]()

SEBU8609

23

General Information

Product Description

The fuel injection pump conforms to requirements for

emissions. If any adjustments to the fuel injection

pump timing and high idle are required, you must

refer to your Perkins distributor your Perkins dealer.

(Table 1, contd)

Bore

84 mm (3.31 inch)

90 mm (3.54 inch)

Stroke

A gerotor oil pump is located in the center of the idler

gear. The engine oil pump sends lubricating oil to the

main oil gallery through a pressure relief valve and an

engine oil filter. The rocker arms receive pressurized

oil through an externally located oil line that runs from

the main oil gallery to the cylinder head.

Displacement

Aspiration

1.496 L (91.291 in

3

)

T(1)

Compression Ratio

Firing Order

22.5:1

1-2-3

Coolant from the bottom of the radiator passes

through the belt driven centrifugal water pump. The

coolant is cooled by the radiator and the temperature

is regulated by a water temperature regulator.

Rotation that is viewed from the

flywheel

Counterclockwise

Valve Lash Setting (Inlet)

Valve Lash Setting (Exhaust)

Injection

0.20 mm (0.008 inch)

0.20 mm (0.008 inch)

Indirect

Engine efficiency, efficiency of emission controls, and

engine performance depend on adherence to correct

operation and maintenance recommendations.

Engine performance and efficiency also depend on

the use of recommended fuels, lubrication oils, and

coolants. Refer to the Operation and Maintenance

Manual, “Maintenance Interval Schedule” for more

information on maintenance items.

(1)

Turbocharged

404F-22 Engine

Engine Specifications

Note: The front end of the engine is opposite the

flywheel end of the engine. The left and the right side

of the engine are determined from the flywheel end.

The No. 1 cylinder is the front cylinder.

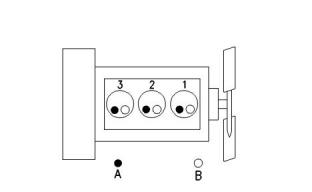

403F-15T Engine

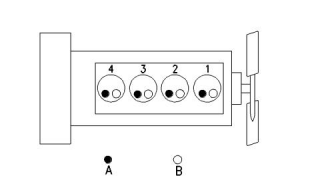

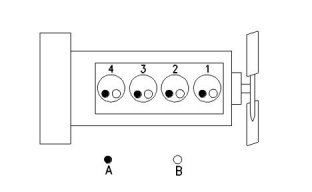

Illustration 22

g00296424

(A) Exhaust valves

(B) Inlet valves

Table 2

404F-22 Engine Specifications

Maximum Operating Speed

(rpm)

3000 rpm

Cylinders and Arrangement

Bore

In-Line 4 cylinder

84.0 mm (3.31 inch)

100.0 mm (3.94 inch)

Illustration 21

g00852304

(A) Exhaust valves

(B) Inlet valves

Stroke

Displacement

Aspiration

2.216 L (135.229 in

3

)

NA(1)

Table 1

403F-15T Engine Specifications

Compression Ratio

Firing Order

23.3:1

Maximum Operating Speed

(rpm)

2800 rpm

In-Line 3 cylinder

1-3-4-2

Cylinders and Arrangement

(continued)

(continued)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

24

SEBU8609

General Information

Product Description

(Table 2, contd)

Electronic Engine Features

Rotation that is viewed from the

flywheel

The engine operating conditions are monitored. The

Electronic Control Module (ECM) controls the

response of the engine to these conditions and to the

demands of the operator. These conditions and

operator demands determine the precise control of

fuel injection by the ECM. The electronic engine

control system provides the following features:

Counterclockwise

Valve Lash Setting (Inlet)

Valve Lash Setting (Exhaust)

Injection

0.20 mm (0.008 inch)

0.20 mm (0.008 inch)

Indirect

(1)

Naturally Aspirated

• Engine monitoring

404F-22T Engine

• Engine speed governing

• System diagnostics

• AftertreatmentRegeneration

• NOx reduction system control on the 404F-22T

engine

For more information on electronic engine features,

refer to the Operation and Maintenance Manual,

“Features and Controls” topic (Operation Section).

Engine Diagnostics

The engine has built-in diagnostics in order to ensure

that the engine systems are functioning correctly. The

operator will be alerted to the condition by a “Stop or

Warning” lamp. Under certain conditions, the engine

horsepower and the vehicle speed may be limited.

The electronic service tool may be used to display the

diagnostic codes.

Illustration 23

g00296424

(A) Exhaust valves

(B) Inlet valves

Table 3

There are four types of diagnostic codes: active code,

logged code, active event and logged event.

404F-22T Engine Specifications

Maximum Operating Speed

(rpm)

Most of the diagnostic codes are logged and stored in

the ECM. For additional information, refer to the

Operation and Maintenance Manual, “Engine

Diagnostics” topic (Operation Section).

3000 rpm

Cylinders and Arrangement

Bore

In-Line 4 cylinder

84.0 mm (3.31 inch)

100.0 mm (3.94 inch)

The ECM provides an electronic governor that

controls the injector output in order to maintain the

desired engine rpm.

Stroke

Displacement

Aspiration

2.216 L (135.229 in

3

)

T(1)

Engine Service Life

Compression Ratio

Firing Order

23.5:1

Engine efficiency and maximum utilization of engine

performance depend on the adherence to proper

operation and maintenance recommendations. In

addition, use recommended fuels, coolants, and

lubricants. Use the Operation and Maintenance

Manual as a guide for required engine maintenance.

1-3-4-2

Rotation that is viewed from the

flywheel

Counterclockwise

Valve Lash Setting (Inlet)

Valve Lash Setting (Exhaust)

Injection

0.20 mm (0.008 inch)

0.20 mm (0.008 inch)

Indirect

Expected engine life is generally predicted by the

average power that is demanded. The average power

that is demanded is based on fuel consumption of the

engine over a period of time. Reduced hours of

operation at full throttle and/or operating at reduced

throttle settings result in a lower average power

demand. Reduced hours of operation will increase

the length of operating time before an engine

overhaul is required.

(1)

Turbocharged

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

SEBU8609

25

General Information

Product Description

Aftermarket Products and Perkins

Engines

Perkins does not warrant the quality or performance

of non-Perkins fluids and filters.

When auxiliary devices, accessories, or consumables

(filters, additives, catalysts,) which are made by other

manufacturers are used on Perkins products, the

Perkins warranty is not affected simply because of

such use.

However, failures that result from the installation

or use of other manufacturers devices,

accessories, or consumables are NOT Perkins

defects. Therefore, the defects are NOTcovered

under the Perkins warranty.

AftertreatmentSystem

The aftertreatment system is approved for use by

Perkins . In order to be emission-compliant only the

approved Perkins aftertreatmentsystem must be

used on a Perkins engine.

This document is printed from SPI². Not for RESALE

![]()

26

SEBU8609

Product Identification Information

Plate Locations and Film Locations

Product Identification

Information

An example of an engine number is

ER*****U000001V.

ER

P

Engine family

Type of engine

i05140083

Plate Locations and Film

Locations

*****

The list number of the engine

Country of manufacture

U

0

The first digit is a production code.

Engine Serial Number

00001

V

Year of Manufacture

Perkins dealers or Perkins distributors need all of

these numbers in order to determine the components

that were included with the engine. This information

permits accurate identification of replacement part

numbers.

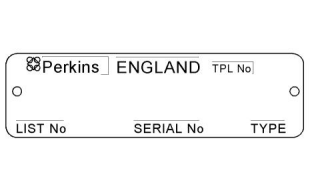

i05140229

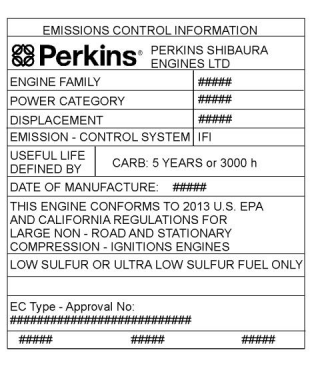

Emissions CertificationFilm

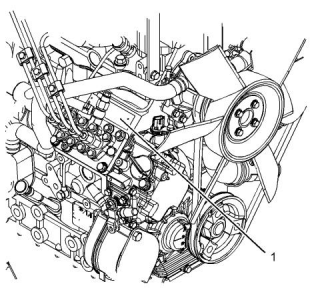

Illustration 24

g02335396

Typical example

(1) serial number plate

Perkins engines are identified by a serial number.

This number is shown on a serial number plate. The

serial number plate is mounted above the fuel

injection pump on the right-hand side of the engine

block.

Illustration 26

g02269574

Typical example

Illustration 25

g01094203

The emissions label, refer to illustration 26 is

installed on the front cover of the engine.

Typical example

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

SEBU8609

27

Product Identification Information

Reference Information

Identifying Numbers on Aftertreatment

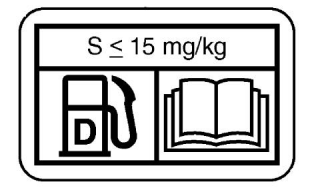

Illustration 27

g02052934

Perkins will supply the fuel label with every engine,

refer to illustration 27 . The equipment manufacturer

must install the label to the equipment. The label must

be attached to the equipment near the inlet of the fuel

tank. This action will comply with the EPA regulations.

The equipment manufacturer may install another fuel

label . If another fuel label is used, the equipment

manufacturer must send a drawing or a photo of the

label to Perkins. This action will ensure compliance of

the label.

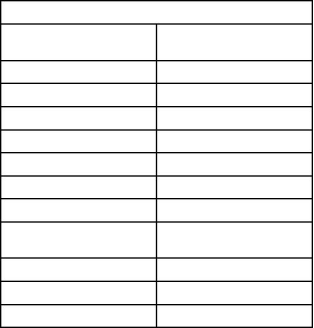

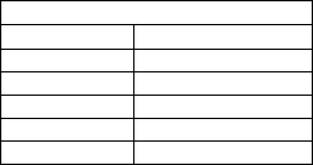

i05157330

Reference Information

Information for the following items may be needed to

order parts. Locate the information for your engine.

Record the information in the appropriate space.

Make a copy of this list for a record. Keep the

information for future reference.

Record for Reference

Engine Model

Engine Serial number

Engine rpm

In-Line fuel filter

Fuel Filter Element

Lubrication Oil Filter

Crankcase Breather Element

Total Lubrication System Capacity

Total Cooling System Capacity

Air Cleaner Element

Fan Belt

Belt for Air Pump

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

28

SEBU8609

Operation Section

Product Lifting

Operation Section

Lifting and Storage

Lifting eyes are designed and installed for specific

engine arrangements. Alterations to the lifting eyes

and/or the engine make the lifting eyes and the lifting

fixtures obsolete. If alterations are made, ensure that

correct lifting devices are provided. Consult your

Perkins dealer or your Perkins distributor for

information regarding fixtures for correct engine

lifting.

i05140249

Product Lifting

Lifting Eyes with Top Mounted

Aftertreatment

Illustration 29

g03321882

i04053009

(1) Front lifting eye

(2) Rear lifting eye

Product Storage

(Engine and Aftertreatment)

Illustration 28

g03274116

Typical example

(1) Front lifting eye

(2) Rear lifting eyes

Perkins are not responsible for damage which may

occur when an engine is in storage after a period in

service.

Note: The engine assembly has three lifting eyes,

refer to illustration 28 .

Use a hoist to remove heavy components. Use an

adjustable lifting beam to lift the engine. All

supporting members (chains and cables) should be

parallel to each other. The chains and cables should

be perpendicular to the top of the object that is being

lifted.

Your Perkins dealer or your Perkins distributor can

assist in preparing the engine for extended storage

periods.

Condition for Storage

The engine must be stored in a water proof building.

The building must be kept at a constant temperature.

Engines that are filled with Perkins ELC will have

coolant protection to an ambient temperature of

−36° C (−32.8° F). The engine must not be subjected

to extreme variations in temperature and humidity.

To remove the engine ONLY, use the lifting eyes that

are on the engine.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

SEBU8609

29

Lifting and Storage

Product Storage

Storage Period

Aftertreatment

No special procedures are required. The exhaust

outlet of the aftertreatment should be capped. Before

storing, the engine and the aftertreatment must be

enclosed in a cover.

An engine can be stored for up to 6 months provided

all the recommendation are adhered to.

Storage Procedure

Monthly Checks

Keep a record of the procedure that has been

completed on the engine.

The crankshaft must be rotated in order to change the

spring loading on the valve train. Rotate the

crankshaft more than 180 degrees. Visibly check for

damage or corrosion to the engine and

aftertreatment.

Note: Do not store an engine that has biodiesel in the

fuel system.

1. Ensure that the engine is clean and dry.

Ensure that the engine and aftertreatment are

covered completely before storage. Log the

procedure in the record for the engine.

a.

b.

If the engine has been operated using

biodiesel, the system must be drained and

new filters installed. The fuel tank will require

flushing.

Fill the fuel system with an ultra low sulfur fuel.

For more information on acceptable fuels refer

to this Operation and Maintenance Manual,

“Fluid recommendations”. Operate the engine

for 15 minutes in order to remove all biodiesel

from the system.

2. Drain any water from the primary filter water

separator. Ensure that the fuel tank is full.

3. The engine oil will not need to be drained in order

to store the engine. Provided the correct

specification of engine oil is used the engine can

be stored for up to 6 months. For the correct

specification of engine oil refer to this Operation

and Maintenance Manual, “Fluid

recommendations”.

4. Remove the drive belts from the engine.

Sealed Coolant System

Ensure that the cooling system is filled with Perkins

ELC, or an antifreeze that meets ASTM D6210

specification.

Open Cooling System

Ensure that all cooling drain plugs have been

opened. Allow the coolant to drain. Install the drain

plugs. Place a vapor phase inhibitor into the system.

The coolant system must be sealed once the vapor

phase inhibitor has been introduced. The effect of the

vapor phase inhibitor will be lost if the cooling system

is open to the atmosphere.

For maintenance procedures ref to this Operation and

Maintenance Manual.

This document is printed from SPI². Not for RESALE

![]()

30

SEBU8609

Features and Controls

Alarms and Shutoffs

Features and Controls

Coolant temperature – The coolant temperature

sensor indicates high jacket water coolant

temperature.

i05142391

Engine oil pressure – The engine oil pressure

sensor or switch, indicates when oil pressure drops

below rated system pressure, at a set engine speed.

Alarms and Shutoffs

Boost pressure (Intake manifold pressure – The

intake manifold pressure sensor checks the rated

pressure in the engine manifold.

• ECM

• DOC

• DPF

• ARD

Electronic Control Module

Diesel Oxidation Catalyst

Intake manifold air temperature – The intake

manifold air temperature sensor indicates high intake

air temperature.

Diesel Particulate Filter

Aftertreatment Regeneration Device

Atmospheric pressure – The atmospheric pressure

sensor checks the air pressure in the location that the

engine is operating.

Shutoffs

The shutoffs are electrically operated or mechanically

operated. The electrically operated shutoffs are

controlled by the ECM.

AftertreatmentAlarms

DOC inlet temperature – The inlet temperature

sensor checks the operating temperature.

Shutoffs are set at critical levels for the following

items:

DPF inlet temperature – The inlet temperature

sensor checks the operating temperature.

• Operating temperature

• Operating RPM

DPF outlet temperature – The outlet temperature

sensor checks the operating temperature.

• Overspeed

Delta P sensor (Differentialpressure) – The sensor

checks the differential pressure within the system.

• Aftertreatment regeneration

The particular shutoff may need to be reset before the

engine will start.

ARD temperature – The sensor checks the

temperature within the burner in the ARD system

NOTICE

Testing

Always determine the cause of the engine shutdown.

Make necessary repairs before attempting to restart

the engine.

Turning the keyswitch to the ON position will check

the indicator lights on the control panel. All the

indicator lights will be illuminated for 2 seconds after

the keyswitch is operated. Replace suspect bulbs

immediately.

Be familiar with the following items:

• Types and locations of shutoff

If any lamps stay illuminated or flashes, the fault must

be investigated immediately. The fault will create a

diagnostic code.

• Conditions which cause each shutoff to function

• The resetting procedure that is required to restart

the engine

Refer to Troubleshooting, “Diagnostic Trouble Code”

for more information.

Alarms

i05140291

The alarms are electrically operated. The operations

of the alarms are controlled by the ECM.

Gauges and Indicators

The alarm is operated by a sensor or by a switch.

When the sensor or the switch is activated, a signal is

sent to the ECM. An event code is created by the

ECM. The ECM will send a signal in order to

illuminate the lamp. Some application may have a

display panel in order to alert the operator.

Your engine may not have the same gauges or all of

the gauges that are described. For more information

about the gauge package, see the OEM information.

Your engine may be equipped with the following

sensors or switches:

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

SEBU8609

31

Features and Controls

Gauges and Indicators

Gauges provide indications of engine performance.

Ensure that the gauges are in good working order.

Determine the normal operating range by observing

the gauges over a period of time.

Tachometer – This gauge indicates

engine speed (rpm). When the throttle

control lever is moved to the full throttle

position without load, the engine is running at

high idle. The engine is running at the full load

rpm when the throttle control lever is at the full

throttle position with maximum rated load.

Noticeable changes in gauge readings indicate

potential gauge or engine problems. Problems may

also be indicated by gauge readings that change

even if the readings are within specifications.

Determine and correct the cause of any significant

change in the readings. Consult your Perkins dealer

or your Perkins distributor for assistance.

NOTICE

To help prevent engine damage, never exceed the

high idle rpm. Overspeeding can result in serious

damage to the engine. The engine can be operated at

high idle without damage, but should never be al-

lowed to exceed high idle rpm.

NOTICE

If no oil pressure is indicated, STOP the engine. If

maximum coolant temperature is exceeded, STOP

the engine. Engine damage can result.

Ammeter – This gauge indicates the

amount of charge or discharge in the

Engine Oil Pressure – The oil pressure

should be greatest after a cold engine is

started. The typical engine oil pressure

with SAE10W30 is 207 to 413 kPa (30 to 60 psi) at

rated rpm.

battery charging circuit. Operation of the

indicator should be to the right side of “0” (zero).

Fuel Level – This gauge indicates the

fuel level in the fuel tank. The fuel level

gauge operates when the “START/

A lower oil pressure is normal at low idle. If the load is

stable and the gauge reading changes, perform the

following procedure:

STOP” switch is in the “ON” position.

Service Hour Meter – The gauge

indicates operating time of the engine.

1. Remove the load.

Indicators and Lamps

• Shutdown lamp

2. Reduce engine speed to low idle.

3. Check and maintain the oil level.

• Warning lamp

Jacket Water Coolant Temperature –

Typical temperature range is 71 to 96°C

(160 to 205°F). The maximum allowable

temperature with the pressurized cooling system

at 90 kPa (13 psi) is 125° C (257° F). Higher

temperatures may occur under certain

conditions. The water temperature reading may

vary according to load. The reading should never

exceed the boiling point for the pressurized

system that is being used.

• Low-pressure oil lamp

For more information on indicator lamps refer to this

Operation and Maintenance Manual, “Monitoring

System (Table for Indicators Lamps)”. All lamps will

be illuminated for 2 seconds in order to check that the

lamps are functioning when the keyswitch is turned to

the ON position. Any lamp that fails to illuminate

during the first 2 second must be replaced. If any of

the lamps stay illuminated, the reason must be

investigated immediately.

If the engine is operating above the normal range and

steam becomes apparent, perform the following

procedure:

AftertreatmentLamps

There are three aftertreatment lamps.

• Regeneration Active Lamp

1. Reduce the load and the engine rpm.

2. Inspect the cooling system for leaks.

• Regeneration Disabled Lamp

• Diesel Particulate Filter (DPF) Lamp

3. Determine if the engine must be shut down

immediately or if the engine can be cooled by

reducing the load.

For information on the aftertreatmentlamps and

warning lamps refer to this Operation and

Maintenance Manual, “Diesel Particulate Filter

Regeneration”

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

32

SEBU8609

Features and Controls

Monitoring System

i05182480

“Warning”

Monitoring System

The orange “Warning” lamp will turn “ON” and the

warning signal is activated continuously in order to

alert the operator that one or more of the engine

parameters is not within normal operating range.

“Derate”

If the Shutdown mode has been selected and the

warning indicator activates, engine shutdown

may take as little as 20 seconds from the time the

warning indicator is activated. Depending on the

application, special precautions should be taken

to avoid personal injury. The engine can be re-

started following shutdown for emergency ma-

neuvers, if necessary.

The orange “Warning” lamp will be “Flashing” . After

the warning, the engine power will be derated. The

warning lamp will begin to flash when the derating

occurs.

The engine will be derated if the engine exceeds

preset operational limits. The engine derate is

achieved by restricting the amount of fuel that is

available for each injection. The amount of this

reduction of fuel is dependent on the severity of the

fault that has caused the engine derate, typically up

to a limit of 50%. This reduction in fuel results in a

predetermined reduction in engine power.

NOTICE

The Engine Monitoring System is not a guarantee

against catastrophic failures. Programmed delays

and derate schedules are designed to minimize false

alarms and provide time for the operator to stop the

engine.

“Shutdown”

The orange warning will be “Flashing” . After the

warning, the engine power will be derated. The

engine will continue at the rpm of the set derate until a

shutdown of the engine occurs. After shutdown the

red stop lamp will illuminate. The engine can be

restarted after a shutdown for use in an emergency.

The following parameters are monitored:

• Coolant temperature

• Intake manifold air pressure

• Oil pressure

A shutdown of the engine after been triggered is

immediate. The engine can be restarted after a

shutdown for use in an emergency. However, the

cause of the initial shutdown may still exist.

• Engine speed/timing

If there is a signal for high coolant temperature, there

will be a 2 second delay in order to verify the

condition.

• Atmospheric pressure (Barometric pressure) if

equipped

• The amount of soot in the Diesel particulate filter

If there is a signal for low oil pressure, there will be a

2 second delay in order to verify the condition.

•

Battery voltage

For information on the operation of the warning lamps

and the shutdown lamp, refer to this Operation and

Maintenance Manual, “Monitoring System (Table for

Indicator Lamps)”. For each of the programmed

modes, refer to Troubleshooting Guide, “Indicator

Lamps” for more information on Indicator Lamps.

Programmable Options and

Systems Operation

For more information or assistance for repairs,

consult your Perkins dealer or your Perkins

distributor.

If the Warning/Derate/Shutdown mode has been

selected and the warning indicator activates,

bring the engine to a stop whenever possible. De-

pending on the application, special precautions

should be taken to avoid personal injury.

The engine can be programmed to the following

modes:

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

SEBU8609

33

Features and Controls

Monitoring System

i05113371

Monitoring System

(Engine Warning Indicators)

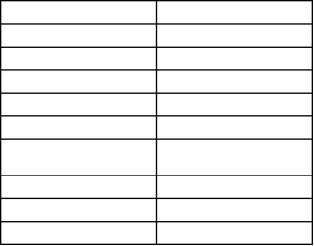

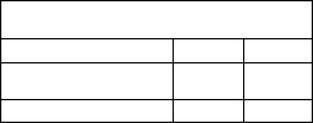

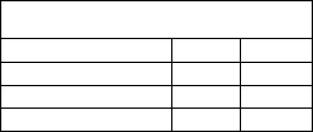

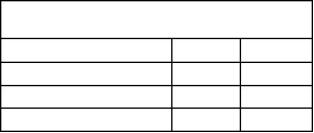

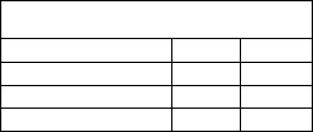

Table 4

Table for Warning Indicators

Warning Indicator

Shutdown

Indicator

Indicator State

Description of the

Indication

Engine Status

Operator Action

ON

ON

Indicator Check

Keyswitch in the ON posi- Power ON, Indicator If any of the Indicators will

tion all Indicators should il- check

not illuminate during the

Indicator check, the fault

must be investigated

immediately.

luminate for 2 seconds.

Engine is not

The aftertreatment Indicatorswill also

be checked during Indicator check.

operating.

If any Indicator stay illumi-

nated or flash, the fault

must be investigated

immediately.

OFF

OFF

OFF

No Fault

Level 1

-

Engine operating

normally.

None

Level 1

ON (Solid)

An active diagnostic code The engine is operat- As soon as possible the

is present.

ing, but one or more

diagnostic codes are

present.

diagnostic code should be

investigated.

Level 2

Flashing

Flashing

OFF

ON

Level 2

Level 3

The ECM has detected an If enabled, the engine Stop the engine.

abnormal condition.

will be derated.

Investigate the fault.

Level 3

Engine condition is

abnormal.

The engine will auto- Stop engine immediately.

matically shut down. Investigate the fault.

If shut down is not en-

abled, the engine can

operate until damage

is coursed.

i05182498

i05142078

Overspeed

Sensors and Electrical

Components

(Engine and Aftertreatment)

• 403F-15T

• 404F-22

• 404F-22T

3000 RPM

3000 RPM

3000 RPM

• ARD

• DOC

• DPF

• ECM

• NRS

Aftertreatment Regeneration Devise

Diesel Oxidation Catalyst

Diesel Particulate Filter

The overspeed is plus 700 RPM above the given

speed for engines shown.

Electronic Control Module

NOx Reduction System

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

34

SEBU8609

Features and Controls

Sensors and Electrical Components

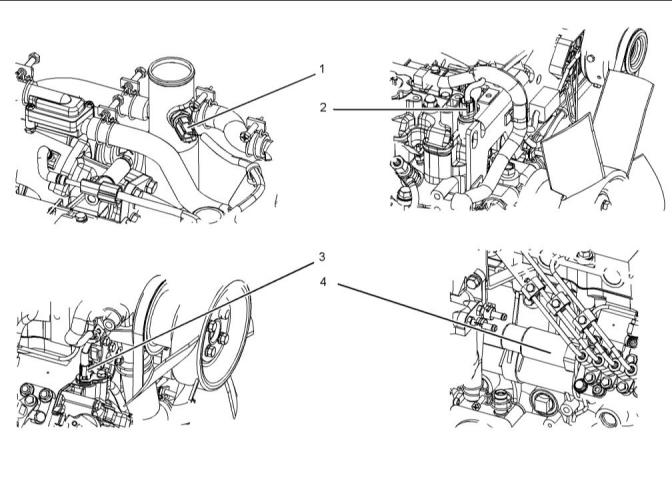

Illustration 30

g03276099

(1) Inlet air temperature sensor

(2) Oil pressure switch

(4) Fuel rack solenoid and position sensor

(5) Glow plugs

(7) Fuel pump/Primingpump

(3) Secondary speed sensor

(6) Resistor for ARD glow plug

This document is printed from SPI². Not for RESALE

![]()

![]()

SEBU8609

35

Features and Controls

Sensors and Electrical Components

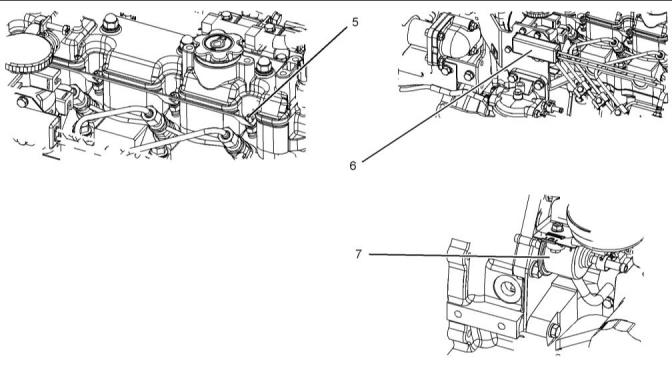

Illustration 31

g03276102

(8) Air pump

(9) Coolant temperature sensor

(10) Alternator

(11) Primary speed sensor

(12) Inlet manifold air pressure sensor

(13) NRS control valve

(14) Solenoid for starting motor

(15) Starting motor

This document is printed from SPI². Not for RESALE

![]()

![]()

36

SEBU8609

Features and Controls

Sensors and Electrical Components

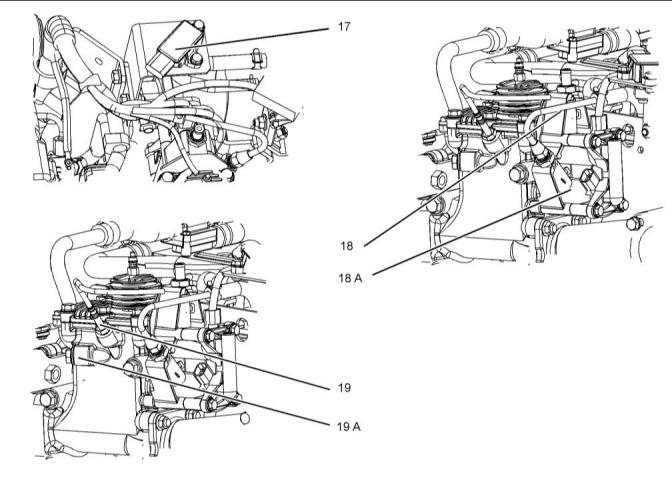

Illustration 32

g03279116

(16) ARD glow plug

(17) DPF pressure differential sensor

(18) ARD injectors

(19) ARD temperature sensor

(20) DOC intake temperaturesensor

(21) DPF intake temperature sensor

(22) DPF outlet temperaturesensor

(23) ECM

The ECM is remotely mounted. The position of ECM

will depend upon the application.

This document is printed from SPI². Not for RESALE

![]()

![]()

SEBU8609

37

Features and Controls

Sensors and Electrical Components

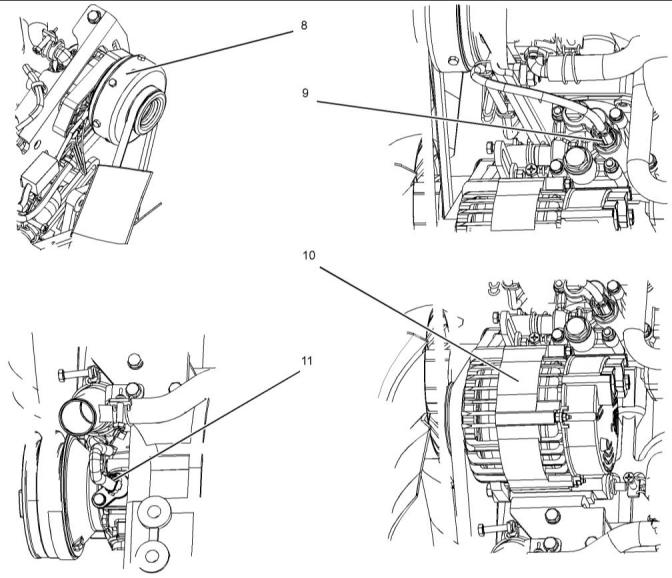

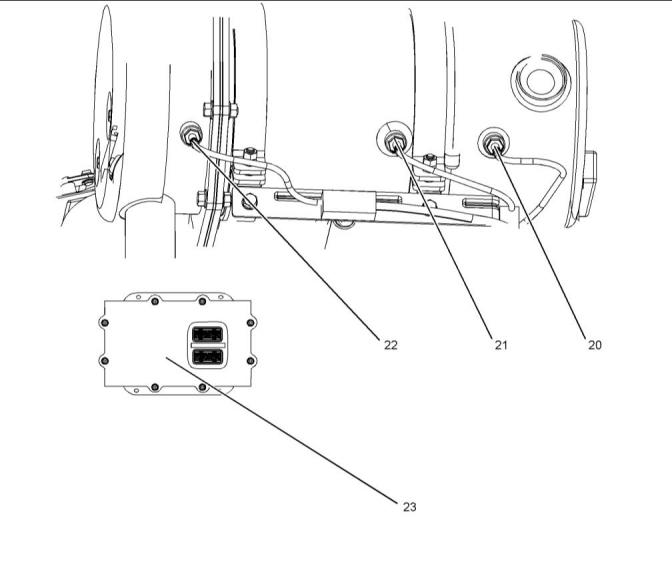

Illustration 33

g03279862

(1) Inlet air temperature

(2) Oil pressure switch

(3) Secondary speed sensor

(4) Fuel rack solenoid and position sensor

This document is printed from SPI². Not for RESALE

![]()

![]()

38

SEBU8609

Features and Controls

Sensors and Electrical Components

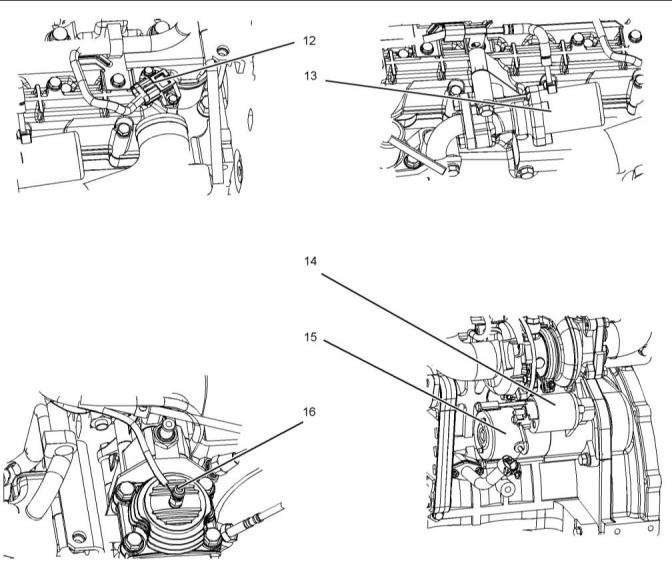

Illustration 34

g03280057

(5) Glow plugs

(6) Resistor for ARD glow plug

(7) Fuel pump/Primingpump

This document is printed from SPI². Not for RESALE

![]()

![]()

SEBU8609

39

Features and Controls

Sensors and Electrical Components

Illustration 35

g03299376

(8) Air pump

(10) Alternator

(9) Coolant temperature sensor

(11) Primary speed sensor

This document is printed from SPI². Not for RESALE

![]()

![]()

,

40

SEBU8609

Features and Controls

Sensors and Electrical Components

Illustration 36

g03299456

(12) Inlet manifold air pressure sensor

(13) NRS control valve

(14) Solenoid for starting motor

(15) Starting motor