珀金斯Perkins2506-15發動機測試調整手冊

詳細描述

Systems Operation

Testing and Adjusting

2506-15 Industrial Engine

M G A (Engine)

MGB (Engine)

M G D (Engine)

Table of Contents

Charging System - Test ........................................ 54

Electric Starting System - Test .............................. 55

Index Section

Systems Operation Section

Index ..................................................................... 56

General Information ................................................ 4

Electronic Control System Components ................. 6

Fuel System ........................................................... 8

Air Inlet and Exhaust System ............................... 12

Lubrication System .............................................. 14

Cooling System .................................................... 16

Basic Engine ......................................................... 17

Electrical System ................................................. 18

Testing and Adjusting Section

Testing and Adjusting

Belt Tension Chart ................................................ 22

Fuel System

Fuel System - Inspect ........................................... 23

Air in Fuel - Test .................................................... 23

Electronic Unit Injector - Adjust ............................. 24

Electronic Unit Injector - Test ................................ 24

Finding Top Center Position for No. 1 Piston ........ 25

Fuel Quality - Test ................................................. 26

Fuel System - Prime ............................................. 26

Fuel System Pressure - Test ................................. 27

Gear Group (Front) - Time .................................... 28

Air Inlet and Exhaust System

Air Inlet and Exhaust System - Inspect ................. 31

Turbocharger - Inspect .......................................... 32

Exhaust Temperature - Test .................................. 34

Engine Crankcase Pressure (Blowby) - Test ........ 35

Engine Valve Lash - Inspect/Adjust ...................... 35

Lubrication System

Engine Oil Pressure - Test .................................... 37

Excessive Bearing Wear - Inspect ........................ 39

Excessive Engine Oil Consumption - Inspect ....... 39

Increased Engine Oil Temperature - Inspect ........ 40

Cooling System

Cooling System - Check (Overheating) ................ 41

Cooling System - Inspect ...................................... 42

Cooling System - Test ........................................... 43

Water Temperature Regulator - Test ..................... 45

Water Pump - Test ................................................ 46

Basic Engine

Piston Ring Groove - Inspect ................................ 47

Connecting Rod Bearings - Inspect ...................... 47

Main Bearings - Inspect ........................................ 47

Cylinder Block - Inspect ........................................ 47

Cylinder Liner Projection - Inspect ........................ 48

Flywheel - Inspect ................................................. 50

Flywheel Housing - Inspect ................................... 51

Vibration Damper - Check .................................... 53

Electrical System

Battery - Test ......................................................... 54

This document has been printed from SPI². Not for Resale

![]()

4

KENR6231

Systems Operation Section

Systems Operation Section

i02550114

General Information

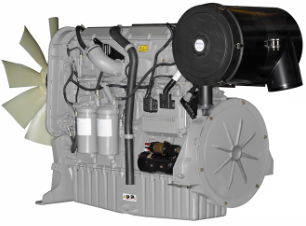

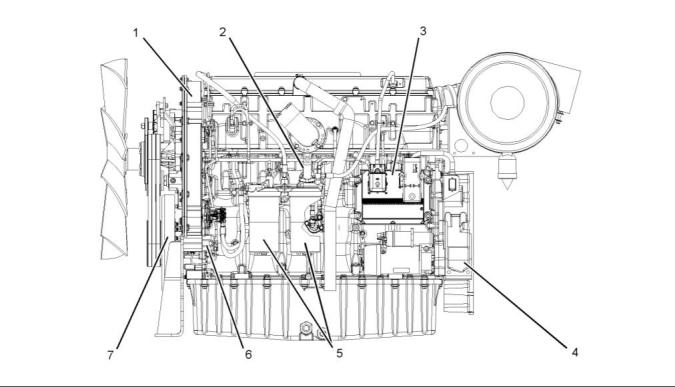

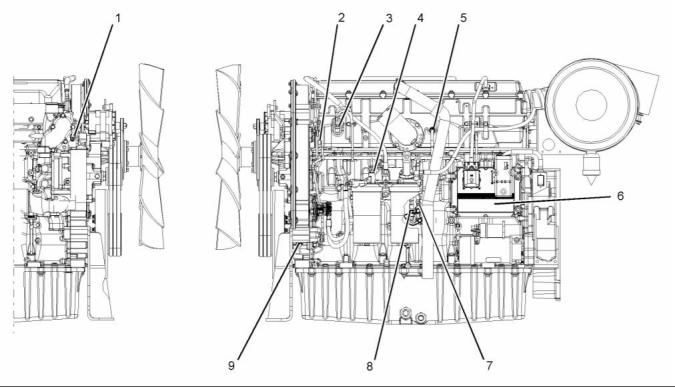

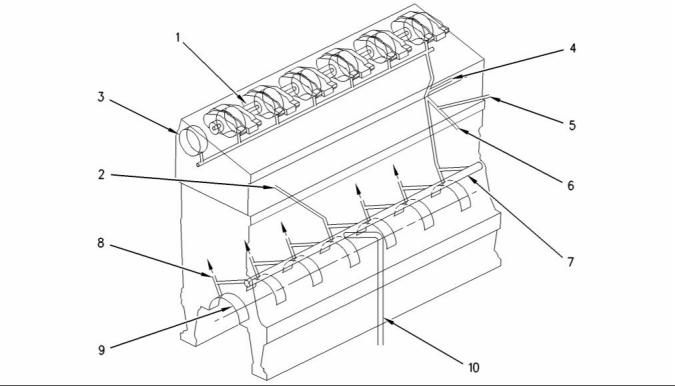

The following model views show the 2506 Engine

features. Due to individual applications, your engine

may appear different from the illustrations.

g01288248

Illustration 1

Typical example

Left side view

(1) Front timing gear housing

(2) Fuel priming pump

(4) Flywheel housing

(5) Fuel filters

(7) Vibration Damper

(3) Electronic Control Module (ECM)

(6) Fuel transfer pump

This document has been printed from SPI². Not for Resale

![]()

![]()

KENR6231

5

Systems Operation Section

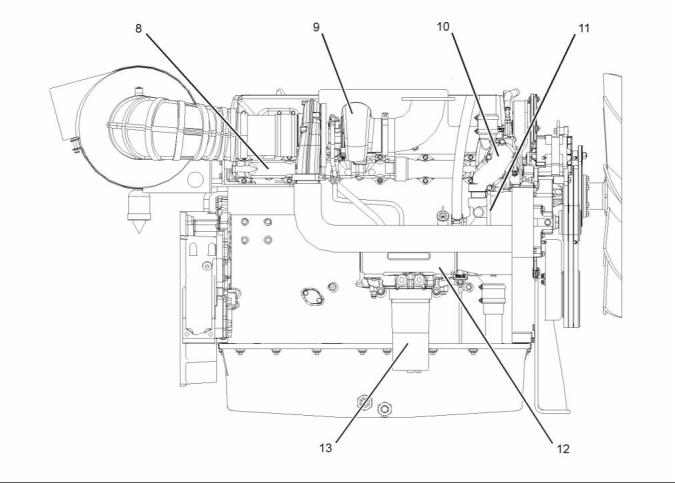

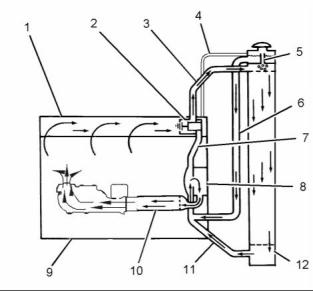

g01288247

Illustration 2

Typical example

Right side view

(8) Exhaust manifold

(9) Turbocharger

(10) Temperature regulator housing

(11) Water pump

(12) Oil cooler

(13) Oil filter

Starting the Engine

Cold mode operation varies the fuel injection amount

for white smoke cleanup. Cold mode operation also

varies the timing for white smoke cleanup. The

engine operating temperature is usually reached

before the walk-around inspection is completed.

The Electronic Control Module (ECM) will

automatically provide the correct amount of fuel that

is necessary to start the engine. If the engine fails

to start in 30 seconds, the starter switch should be

released. The starting motor should be allowed to

cool for 30 seconds before being used again.

Cold Mode Operation

The ECM will set the cold start strategy when the

coolant temperature is below 18 °C (64 °F).

Cold mode operation will be deactivated when any of

the following conditions have been met:

• Coolant temperature reaches 18 °C (64 °F).

• The engine has been running for fourteen minutes.

This document has been printed from SPI². Not for Resale

![]()

![]()

6

KENR6231

Systems Operation Section

i02589727

Electronic Control System

Components

g01279775

Illustration 3

(1) Coolant temperature sensor

(2) Camshaft position sensor

(3) Inlet manifold pressure sensor

(4) Fuel temperature sensor

(7) Engine oil pressure sensor

(8) Atmospheric pressure sensor

(9) Crankshaft position sensor

(5) Inlet manifold temperature sensor

(6) Electronic control module (ECM)

The electronic control system is integrally designed

into the engine’s fuel system and the engine’s air

inlet and exhaust system in order to electronically

control the fuel delivery and the injection timing. The

electronic control system provides increased timing

control and fuel air ratio control in comparison to

conventional mechanical engines. Injection timing

is achieved by precise control of injector firing time,

and engine rpm is controlled by adjusting the firing

duration. The Electronic Control Module (ECM)

energizes the solenoid in the unit injector in order to

start the injection of fuel. Also, the ECM de-energizes

the unit injector solenoids in order to stop injection

of fuel. Refer to Systems Operation, Testing and

Adjusting, “Fuel System” for a complete explanation

of the fuel injection process.

• Controls

• Outputs

An input component is one that sends an electrical

signal to the ECM. The signal that is sent varies in

one of the following ways:

• Voltage

• Frequency

• Pulse width

The variation of the signal is in response to a change

in some specific system of the vehicle. The ECM

sees the input sensor signal as information about the

condition, environment, or operation of the vehicle.

The engine uses the following types of electronic

components:

• Inputs

This document has been printed from SPI². Not for Resale

![]()

![]()

KENR6231

7

Systems Operation Section

A control component (ECM) receives the input

signals. Electronic circuits inside the control

component evaluate the signals from the input

components. These electronic circuits also supply

electrical energy to the output components of the

system. The electrical energy that is supplied to

the output components is based on predetermined

combinations of input signal values.

An output component is one that is operated by a

control module. The output component receives

electrical energy from the control component. The

output component uses that electrical energy in one

of two ways. The output component can use that

electrical energy in order to perform work. The output

component can use that electrical energy in order to

provide information.

This document has been printed from SPI². Not for Resale

![]()

8

KENR6231

Systems Operation Section

i02550058

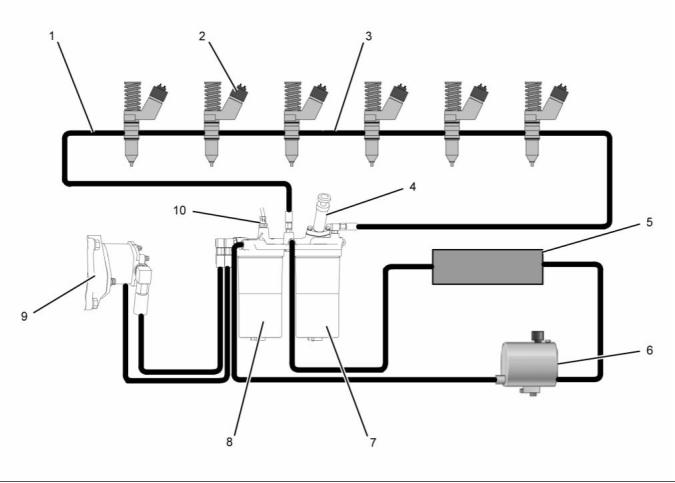

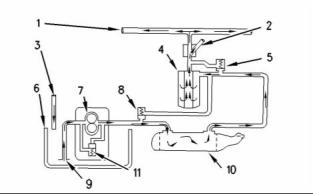

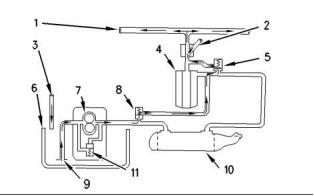

Fuel System

g01282152

Illustration 4

Fuel system schematic

(1) Fuel return line

(2) Electronic unit injectors

(3) Fuel gallery

(6) Fuel tank

(7) Secondary fuel filter

(8) Primary fuel filter

(4) Fuel priming pump

(5) Fuel cooler

(9) Fuel transfer pump

(10) Fuel temperature sensor

The fuel supply circuit is a conventional design for

engines with electronic unit injection. A fuel tank (6)

is used to store the fuel prior to use by the engine. A

primary fuel filter/water separator (8) is placed into

the fuel supply circuit in order to remove large debris

from the fuel. This debris may have entered the

fuel tank during fueling. The debris may have also

entered the fuel tank through the vent for the fuel

tank. The primary filter element also separates water

from the fuel. The water is collected in the bowl at the

bottom of the primary fuel filter/water separator.

Note: The inlet fuel temperature to the fuel transfer

pump must not exceed 79 °C (175 °F) when the

engine has reached normal operating temperature.

Fuel temperatures above 79 °C (175 °F) will reduce

the life of the fuel transfer pump check valves. The

fuel efficiency and the engine power output are

reduced when the fuel temperature increases from

30 °C (86 °F) to 70 °C (158 °F).

This document has been printed from SPI². Not for Resale

![]()

![]()

KENR6231

9

Systems Operation Section

Fuel from the tank (6) flows to the fuel filter base.

The fuel filter base contains the primary fuel filter

and the secondary fuel filter. The fuel flows through

cored passages in the fuel filter base. The fuel

priming pump (4) is mounted on the fuel filter base.

The fuel priming pump is used in order to manually

pump the fuel into the fuel system after the system,

or parts of the system have been drained. The fuel

priming pump is used in order to refill the fuel system

after air has been introduced into the system. For

more information on priming the fuel system, refer

to Systems Operation, Testing and Adjusting, “Fuel

System - Prime”.

The fuel exits the fuel gallery and returns to the fuel

filter base. A pressure regulating valve is located in

the fuel filter base. The pressure regulating valve

regulates the pressure for the fuel system. A sufficient

amount of back pressure is maintained in the system

in order to ensure a continuous availability of fuel to

the electronic unit injectors. The fuel flows from the

fuel filter base to the fuel cooler (5). The fuel flows

from the fuel cooler (5) back to the tank (6).

Fuel System Electronic Control

Circuit

As the fuel flows through cored passages in the fuel

filter base, the fuel is directed into the primary fuel

filter (8). Fuel flows out of the fuel filter and returns

to the passages in the fuel filter base. Prior to exiting

the fuel filter base, the fuel temperature is sampled

by the fuel temperature sensor (10). The signals

that are generated by the sensors are used by the

engine control in order to monitor the condition of the

engine’s components.

The fuel flows from the fuel filter base to the fuel

transfer pump (9). The fuel transfer pump (9) is a gear

type pump with fixed clearances. The fuel transfer

pump (9) incorporates an internal relief valve that

protects the fuel system from extreme pressure. In

the case of extreme pressure, fuel is redirected back

to the inlet of the fuel transfer pump (9). An outlet

check valve is used in order to prevent pressurized

fuel leakage back through the pump. The fuel transfer

pump (9) is located in the front of the engine. The fuel

transfer pump (9) is driven by the front gear train.

g00451841

Illustration 5

Electronic governor

(1) Signals to the electronic unit injectors

(2) Fuel injection control

(3) Fuel position

(4) Electronic governor

(5) Desired rpm

(6) Coolant temperature

(7) TC for No. 1 cylinder

(8) FRC fuel position

The fuel flows from the fuel transfer pump (9) to the

secondary fuel filter (7). The fuel is filtered in order

to remove small abrasive particles that will cause

premature wear to fuel system components. The fuel

flows from the secondary fuel filter (7) to the fuel filter

base.

(9) Rated fuel position

(10) FCR maps

(11) Torque maps

(12) Engine speed/timing sensor

(13) Engine speed/timing signals’ interpreter

(14) Engine rpm

(15) Coolant temperature sensor

(16) Boost pressure sensor

(17) Boost pressure

The fuel is then directed from the fuel filter base

through the fuel return line (1) to fuel manifold (3) that

runs the length of the cylinder head. A continuous

flow of fuel is supplied to the electronic unit injectors

(2) in order to perform the following tasks:

The injection pump, the fuel lines, and the nozzles

that are used in the traditional Perkins diesel engines

have been replaced with an electronically controlled,

mechanically actuated electronic unit injector in each

cylinder. A solenoid on each injector controls the

amount of fuel that is delivered by the injector. An

Electronic Control Module (ECM) sends a signal to

each injector solenoid in order to provide complete

control of the engine.

• Supply fuel for injection

• Remove excessive heat from the injectors.

• Remove air that may accumulate in the fuel

system.

This document has been printed from SPI². Not for Resale

![]()

![]()

10

KENR6231

Systems Operation Section

Fuel Injection

Electronic Unit Injector Mechanism

The ECM controls the amount of fuel that is injected

by varying the signals that are sent to the injectors.

The ECM sends a high voltage signal to the solenoid

in order to energize the solenoid. The injectors

will inject fuel only while the injector solenoid is

energized. By controlling the timing and the duration

of the voltage signal, the ECM can control injection

timing and the amount of fuel that is injected.

The ECM sets certain limits on the amount of fuel that

can be injected. “FRC” is a limit which controls the

amount of air and of fuel for the purpose of emission

control. This limit is based on the boost pressure.

When the ECM senses a higher boost pressure, the

ECM increases the “FRC” limit. “Rated Fuel Pos” is

a limit that is based on the horsepower rating of the

engine. This is similar to the rack stops and to the

torque spring on a mechanically governed engine.

“Rated Fuel Pos” provides horsepower and torque

curves for a specific engine family and for a specific

engine rating. All of these limits are programmed into

the personality module by the factory. These limits

are not programmable by the service technician.

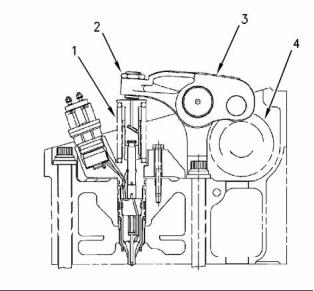

g00291269

Illustration 6

Electronic unit injector mechanism

(1) Electronic unit injector

(2) Adjusting nut

Injection timing depends on three factors: the engine

speed (rpm), the engine load, and the operational

conditions of the engine. The ECM determines the

top center position of No. 1 cylinder from the signal

that is provided by the engine speed/timing sensor.

The ECM decides when the injection should occur

relative to the top center position. The ECM then

provides the signal to the electronic unit injector at

the desired time.

(3) Rocker arm assembly

(4) Camshaft lobe

The electronic unit injector mechanism provides

the downward force that is required to pressurize

the fuel in the electronic unit injector pump. The

electronic unit injector (1) allows fuel to be injected

into the combustion chamber with precise timing.

Movement is transmitted from the camshaft lobe (4)

for the electronic unit injector through the rocker arm

assembly (3) to the top of the electronic unit injector.

The adjusting nut (2) allows the injector lash to be

adjusted. For the proper setting of the injector lash,

refer to the topic on adjustment of the electronic unit

injector in Systems Operation, Testing and Adjusting,

“Electronic Unit Injector - Adjust”.

This document has been printed from SPI². Not for Resale

![]()

![]()

KENR6231

11

Systems Operation Section

Electronic Unit Injector

As the electronic unit injector mechanism transfers

the force to the top of the electronic unit injector,

spring (1) is compressed and plunger (4) is driven

downward. This action displaces fuel through the

valve in solenoid valve assembly (3), and into the

return manifold to the fuel tank. As the plunger travels

downward, the passage in barrel (5) is closed by the

outside diameter of the plunger. The passages within

body (10) and along check valve (11) to the injector

tip already contain fuel for injection. After the passage

in the plunger barrel is closed, the injector is ready for

injection at any time. The start of injection relies on

the software in the Electronic Control Module (ECM).

When the solenoid valve assembly is energized

from a signal across solenoid connection (2), the

valve closes and fuel pressure is elevated in the

injector tip. Injection begins at 34500 ± 1900 kPa

(5000 ± 275 psi) as the force of spring (8) above

spacer (9) is overcome. The check valve begins

to lift from the valve seat. The pressure continues

to rise as the plunger cycles through a full stroke.

After the correct amount of fuel has been discharged

into the cylinder, the ECM removes the signal to the

solenoid connection. The solenoid valve assembly

is de-energized and the valve in the solenoid valve

assembly is opened. The high pressure fuel is then

dumped through the spill port and into the fuel return

manifold. The fuel is then returned to the fuel tank.

The check valve in the injector tip seats as the

pressure in the tip decreases.

The duration of injection meters the fuel that is

consumed during the fuel injection process. Injection

duration is controlled by the governor logic that is

programmed into the ECM.

g00984466

Illustration 7

Electronic unit injector

(1) Spring

As the camshaft lobe rotates past the point of

maximum lobe lift, the force on top of the electronic

unit injector is removed and the spring for the injector

mechanism is allowed to expand. The plunger returns

to the original position. This uncovers the fuel supply

passage into the plunger barrel in order to refill the

injector pump body. The fuel at low pressure is again

allowed to circulate through the fuel injector body.

After circulating through the fuel injector body, the

fuel flows out of the spill port. This continues until the

solenoid valve assembly is re-energized for another

injection cycle.

(2) Solenoid connection to the Electronic Control Module (ECM)

(3) Solenoid valve assembly

(4) Plunger assembly

(5) Barrel

(6) Seal

(7) Seal

(8) Spring

(9) Spacer

(10) Body

(11) Check valve

Fuel at low pressure from the fuel supply manifold

enters the electronic unit injector at the fill port

through drilled passages in the cylinder head.

This document has been printed from SPI². Not for Resale

![]()

![]()

12

KENR6231

Systems Operation Section

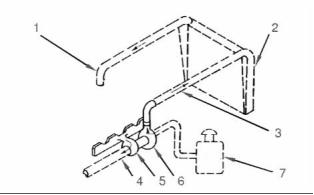

i02550062

Air Inlet and Exhaust System

Air is forced from the aftercooler into inlet manifold

(1). The air flow from the inlet port into the cylinders

is controlled by inlet valves.

g00615497

Illustration 9

g01046036

Air inlet and exhaust system

Illustration 8

Air inlet and exhaust system schematic

(2) Aftercooler core

(4) Exhaust outlet

(1) Inlet to the engine

(5) Turbine side of turbocharger

(6) Compressor side of turbocharger

(8) Exhaust manifold

(9) Exhaust valve

(2) Aftercooler core

(3) Inlet air line

(4) Exhaust outlet from turbocharger

(5) Turbine side of turbocharger

(6) Compressor side of turbocharger

(7) Air cleaner

(10) Inlet valve

(11) Air inlet

Each cylinder has two inlet valves (10) and two

exhaust valves (9) in the cylinder head. The inlet

valves open on the inlet stroke. When the inlet valves

open, compressed air from the inlet port within the

inlet manifold is pushed into the cylinder. The inlet

valves close when the piston begins the compression

stroke. The air in the cylinder is compressed and the

fuel is injected into the cylinder when the piston is

near the top of the compression stroke. Combustion

begins when the fuel mixes with the air. The force of

combustion pushes the piston on the power stroke.

The exhaust valves open and the exhaust gases

are pushed through the exhaust port into exhaust

manifold (8). After the piston finishes the exhaust

stroke, the exhaust valves close and the cycle begins

again.

The engine components of the air inlet and exhaust

system control the quality of air and the amount of

air that is available for combustion. The components

of the air inlet and exhaust system are the following

components:

• Air cleaner

• Turbocharger

• Aftercooler

• Cylinder head

• Valves and valve system components

• Piston and cylinder

• Exhaust manifold

Exhaust gases from the exhaust manifold flow

into the turbine side of turbocharger (5). The high

temperature exhaust gases cause the turbocharger

turbine wheel to turn. The turbine wheel is connected

to the shaft that drives the compressor wheel.

Exhaust gases from the turbocharger pass through

exhaust outlet (4), through a muffler, and through an

exhaust stack.

The turbocharger compressor wheel pulls inlet air

through the air cleaner and into the air inlet. The air

is compressed and this causes the air to become hot.

The air flows through aftercooler core (2) and the

temperature of the compressed air lowers. This helps

to provide increased horsepower output. Aftercooler

core (2) is a separate cooler core that is mounted in

front of the engine radiator. The engine fan causes

ambient air to move across both cores. This cools the

turbocharged inlet air and the engine coolant.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

KENR6231

13

Systems Operation Section

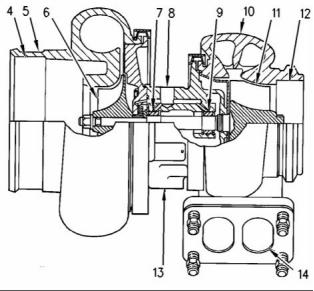

Turbocharger

Valves And Valve Mechanism

g01046041

g00291085

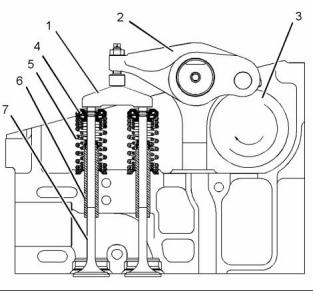

Illustration 11

Valve system components

Illustration 10

Turbocharger

(1) Valve bridge

(2) Rocker arm

(3) Camshaft

(4) Rotocoil

(4) Air inlet

(5) Compressor housing

(6) Compressor wheel

(7) Bearing

(5) Valve spring

(6) Valve guide

(7) Valve

(8) Oil inlet port

(9) Bearing

(10) Turbine housing

(11) Turbine wheel

(12) Exhaust outlet

(13) Oil outlet port

(14) Exhaust inlet

The valves and the valve mechanism control the flow

of inlet air into the cylinders during engine operation.

The valves and the valve mechanism control the flow

of exhaust gases out of the cylinders during engine

operation.

Turbocharger (3) is mounted to exhaust manifold (2)

of the engine. All of the exhaust gases go from the

exhaust manifold through the turbocharger.

The exhaust gases enter the turbocharger and the

turbine wheel is turned. Because the turbocharger

turbine wheel is connected by a shaft to the

turbocharger compressor wheel, the turbine wheel

and the compressor wheel turn at very high speeds.

The rotation of the compressor wheel pulls clean

air through the compressor housing air inlet. The

action of the compressor wheel blades causes a

compression of the inlet air. This compression allows

a larger amount of air to enter the engine. With more

air in the engine, the engine is able to burn more fuel.

The overall effect is an increase in power.

Bearing (7) and bearing (9) in the turbocharger use

engine oil that is under pressure for lubrication. The

lubrication for the bearings flows through oil inlet port

(8) and into the inlet port in the center section of the

turbocharger cartridge. The oil exits the turbocharger

through oil outlet port (13). The oil then returns to

the engine oil pan through the oil drain line for the

turbocharger.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

14

KENR6231

Systems Operation Section

Rotocoils (4) cause the valves to rotate while the

engine is running. Valve rotation provides a longer

service life. Valve rotation also minimizes carbon

deposits on the valves.

Adjustable idler gear (10) is designed to provide the

required gear backlash between nonadjustable idler

gear (11) and camshaft gear (9). If the cylinder head is

removed, tolerances of the components will change.

The components that change are the cylinder head

and the head gasket. The adjustable idler gear must

be relocated. For information on setting the correct

backlash, refer to Systems Operation, Testing and

Adjusting, “Gear Group (Front) - Time”.

The camshaft drive gear has integral pendulums

which act as a vibration damper for the front gear

group. These pendulums are designed to counteract

the torsional forces from the injector pulses. This

eliminates vibration and noise. The engine also runs

smoother at all operating speeds.

i02550074

Lubrication System

g01033757

Illustration 12

Components of the gear train

Lubrication System Components

(8) Timing mark

The lubrication system has the following components:

(9) Camshaft gear

(10) Adjustable idler gear

(11) Idler gear

• Oil pan

(12) Timing mark

(13) Cluster gear

(14) Crankshaft gear

(15) Oil pump gear

• Oil pump

• Oil cooler

The inlet valves and the exhaust valves are opened

by the valve mechanism. The inlet valves and

the exhaust valves are also closed by the valve

mechanism. This occurs as the rotation of the

crankshaft causes camshaft (3) to rotate. Camshaft

gear (9) is driven by a series of two idler gears (10)

and (11). Idler gear (11) is driven by cluster gear (13).

Cluster gear (13) is driven by crankshaft gear (14).

Timing mark (12) and timing mark (8) are aligned in

order to provide the correct relationship between the

piston and the valve movement.

• Oil filter

• Turbocharger oil lines

• Oil passages for the cylinder block

The camshaft has three lobes for each cylinder.

One lobe operates the inlet valves. A second lobe

operates the exhaust valves. The third lobe operates

the unit injector mechanism. The camshaft lobes turn

and the rocker arms move. Movement of the rocker

arms will make the inlet and exhaust valve bridges

move. These bridges allow one rocker arm to actuate

two valves at the same time. Each cylinder has two

inlet valves and two exhaust valves. Each valve has

one valve spring (5). The spring closes the valve.

This document has been printed from SPI². Not for Resale

![]()

![]()

KENR6231

15

Systems Operation Section

Oil Flow Through The Oil Filter And Oil

Cooler

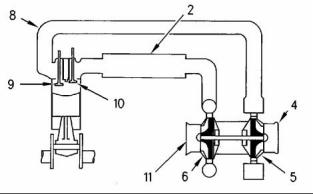

g00562383

Illustration 14

Oil flow when the engine Is cold.

g00562123

Illustration 13

Oil flow when the engine is warm.

(1) Oil manifold

(2) Oil supply line

(3) Oil return line

(4) Oil filter

(1) Oil manifold

(2) Oil supply line

(5) Bypass valve for the oil filter

(6) Oil pan

(3) Oil return line

(4) Oil filter

(7) Oil pump

(5) Bypass valve for the oil filter

(6) Oil pan

(8) Bypass valve for the oil cooler

(9) Suction lines

(7) Oil pump

(10) Oil cooler

(8) Bypass valve for the oil cooler

(9) Suction lines

(11) Bypass valve for the oil pump

(10) Oil cooler

When the engine is cold, oil is drawn from the oil

pan (6) through the suction lines (9) to the oil pump

(7). When the oil is cold, an oil pressure differential

in the bypass valves causes the bypass valves to

open. These bypass valves then provide immediate

lubrication to all of the engine components when cold

oil with high viscosity causes a restriction to oil flow

through the oil cooler (10) and the oil filter (4). The oil

pump then pushes the cold oil through the bypass

valve (8) for the oil cooler and through the bypass

valve (5) for the oil filter. The oil then goes to the oil

manifold (1) in the cylinder block and to the supply

line (2) for the turbocharger. Oil from the turbocharger

goes back through the oil return line (3) to the oil pan.

(11) Bypass valve for the oil pump

When the engine is warm, oil is drawn from the oil

pan (6) through the suction lines (9) to the oil pump

(7). The oil pump pushes the hot oil through the oil

cooler (10). The oil is then sent to the oil filter (4).

Oil from the oil filter is sent to the oil manifold (1) in

the cylinder block and to the oil supply line (2) for the

turbocharger. Oil from the turbocharger goes back

through the oil return line (3) to the oil pan.

When the oil is warm, an oil pressure differential in

the bypass valves also causes the bypass valves to

close. There is normal oil flow through the oil cooler

and the oil filter.

The bypass valves will also open when there is

a restriction in the oil cooler or the oil filter. This

prevents a restricted oil filter or a restricted oil cooler

from stopping the lubrication of the engine. The

system pressure is limited by the oil pump bypass

valve (11).

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

16

KENR6231

Systems Operation Section

Oil Flow In The Engine

g00431790

Illustration 15

Engine oil flow schematic

(1) Rocker arm shaft

(5) Oil passage to the fixed idler stub shaft

(6) Oil passage to cluster idler gear

(7) Oil manifold

(9) Crankshaft main bearings

(10) Oil passage from filter

(2) Oil passage to air compressor

(3) Camshaft bearing journals

(4) Oil passage to adjustable idler gear

(8) Piston cooling jet

The oil from the oil manifold (7) is sent under

pressure through drilled passages to the crankshaft

main bearings (9). The oil flows through drilled holes

in the crankshaft. This oil lubricates the connecting

rod bearings. A small amount of oil is sent to the

piston cooling jets (8). The piston cooling jets spray

oil on the underside of the pistons.

Oil flows into the cylinder head via a hollow locating

dowel in the top deck of the cylinder block. Oil travels

to the camshaft bearing journals (3) and the three

center rocker arm shaft supports through drilled

passages in the cylinder head. The supports supply

oil to each rocker shaft. Oil flows to the bushings of

the fuel injector rocker arm through holes in the rocker

arm shaft (1). This same oil lubricates the valve and

the rollers. Oil flows through drilled passages in the

rocker arms. This oil lubricates the roller, the valve

bridge and the contact surfaces of the actuator of the

unit injector. Splash oil lubrication is used to lubricate

other components of the valve system.

Oil flows through passages in the timing gear housing

and the accessory drive gear. This oil flows to the air

compressor through the oil passage (2).

Oil passage (4) provides oil to the adjustable idler

gear. Oil passage (5) provides oil to the fixed idler

gear. Oil passage (6) provides oil to the cluster gear.

The oil flows through a passage in the shafts of the

gears.

Excess oil returns to the engine oil pan.

i02550118

Cooling System

There is a pressure control valve in the oil pump.

This valve controls the pressure of the oil that flows

from the oil pump.

Oil passage (9) provides lubrication to the rear

crankshaft seal. This ensures a long service life for

the rear crankshaft seal.

This engine has a pressure type cooling system that

is equipped with a shunt line.

This document has been printed from SPI². Not for Resale

![]()

![]()

KENR6231

17

Systems Operation Section

A pressure type cooling system gives two

The water temperature regulator (2) is closed when

the engine is cold. The coolant flows through the

regulator housing and pipe (7) back to water pump

(8).

advantages. First, the cooling system can be

operated safely at a temperature that is higher than

the boiling point of water. Next, cavitation in the water

pump is prevented. It is more difficult for air or steam

pockets to be made in the cooling system.

If the coolant is at normal operating temperature,

the water temperature regulator (2) opens and the

coolant flows to the radiator (12) through the outlet

pipe (3). The coolant becomes cooler as the coolant

moves through the radiator. When the coolant gets to

the bottom of the radiator, the coolant goes through

the inlet pipe (11) and into the water pump (8).

Note: Use Perkins ELC in an Air-To-Air Aftercooler

system. Refer to Operation and Maintenance Manual,

“Fluid Recommendations” for more information. This

keeps the temperature range of the coolant high

enough for efficient performance.

Note: The water temperature regulator (2) is an

important part of the cooling system. The water

temperature regulator (2) divides the coolant flow

between the radiator (12) and the bypass pipe (7).

This will maintain the correct temperature. If the

water temperature regulator is not installed in the

system, there is no mechanical control. Most of the

coolant will go through the bypass. This will cause

the engine to overheat in hot weather. If a higher

volume of coolant goes through the radiator, the

engine will not reach normal operating temperatures.

This occurs during cold weather.

Shunt line (6) gives several advantages to the cooling

system. The shunt line gives a positive coolant

pressure at the water pump inlet that prevents pump

cavitation. A small flow of coolant constantly goes

through shunt line (6) to the inlet of water pump

(8). This causes a small amount of coolant to move

constantly through the vent tube (5). The flow through

the vent tube is small and the volume of the upper

compartment is large. Air in the coolant is removed

as the coolant goes into the upper compartment.

g01096647

Illustration 16

Cooling system for a warm engine

(1) Cylinder head

(2) Water temperature regulator

(3) Outlet pipe

(4) Vent line

The vent line is used to fill the cooling system with

coolant for the first time. This will purge any air out of

the top of a bottom filled system.

(5) Vent tube

(6) Shunt line

(7) Pipe

(8) Water pump

(9) Cylinder block

(10) Oil cooler

(11) Inlet pipe

i02550119

Basic Engine

(12) Radiator

In operation, the water pump (8) sends most of the

coolant from the radiator (12) to the oil cooler (10).

Cylinder Block Assembly

The coolant from the oil cooler (10) goes into the

cylinder block (9) through a bonnet and an elbow.

The coolant goes around the cylinder liners, through

the water directors and into the cylinder head.

Passages supply the lubrication for the crankshaft

bearings and the piston crowns. These passages

are cast into the cylinder block. Oil is supplied to the

passages by the cylinder block’s oil manifold.

The water directors send the flow of coolant around

the valves and the passages for exhaust gases in the

cylinder head. The coolant then goes to the front of

the cylinder head. At this point, water temperature

regulator (2) controls the direction of coolant flow.

The cylinder liner is an induction hardened liner. A

steel spacer plate provides improved reusability and

durability.

This document has been printed from SPI². Not for Resale

![]()

![]()

18

KENR6231

Systems Operation Section

Cylinder Head Assembly

Camshaft

The cylinder head is a one-piece cast iron head. The

cylinder head supports the camshaft. Steel reinforced

bearings are pressed into each bore. The bearings

are lubricated under pressure. Bridge dowels have

been eliminated as the valve train uses floating valve

bridges.

The camshaft has three lobes at each cylinder.

These lobes allow the camshaft to operate the unit

injector, the exhaust valves, and the inlet valves. The

camshaft is supported in the cylinder head by seven

journals which are fit with bearings. The camshaft

gear contains integral roller dampers that counteract

the torsional vibrations that are generated by the

high fuel pressure during fuel injector operation. The

design reduces gear train noise. The camshaft is

driven by an adjustable idler gear which is turned by

a fixed idler gear which is turned by a cluster idler

gear in the front gear train. Each bearing journal is

lubricated from the oil manifold in the cylinder head.

A thrust plate that is located at the front controls the

end play of the camshaft. Timing of the camshaft is

accomplished by aligning marks on the crankshaft

gear and idler gear, and camshaft gear with a mark

on the front timing plate.

Thermal efficiency is enhanced by the use of

stainless steel thermal sleeves in each exhaust port.

The sleeves reduce the amount of heat rejection to

the cooling system. The sleeves then transfer the

thermal energy to the turbocharger.

The unit injector is mounted in a stainless steel

adapter. This adapter has been pressed into the

cylinder head injector bore.

Pistons, Rings And Connecting

Rods

i02554889

The piston is a one-piece steel design that is retained

by the piston pin to the small end of the connecting

rod. The pistons have three rings that are located

in grooves in the steel crown. These rings seal the

combustion gas. The rings provide control of the oil.

The top ring has a barrel face. The second ring has

a tapered face and the ring has a coating of chrome

finish for the face. The third ring is the oil ring. The

third ring has a coil spring expander.

Electrical System

Grounding Practices

Proper grounding for the machine electrical system

and engine electrical systems is necessary for

proper machine performance and reliability. Improper

grounding will result in uncontrolled electrical circuit

paths and unreliable electrical circuit paths.

The connecting rod is a conventional design. The

cap of the connecting rod is attached to the shank by

two bolts that are threaded into the shank. Each side

of the small end of the connecting rod is machined

at an angle of 12 degrees in order to fit within the

piston cavity.

Uncontrolled engine electrical circuit paths can result

in damage to main bearings, crankshaft bearing

journal surfaces, and aluminum components.

To ensure proper functioning of the vehicle and

engine electrical systems, an engine-to-frame ground

strap with a direct path to the negative battery post

must be used. This may be provided by way of a

starting motor ground, a frame to starting motor

ground, or a direct frame to engine ground.

Crankshaft

The crankshaft converts the combustion force in the

cylinder into rotating torque. A vibration damper is

used at the front of the crankshaft in order to reduce

the torsional vibrations.

An engine-to-frame ground strap must be used in

order to connect the grounding stud of the engine to

the frame of the vehicle and to the negative battery

post.

The crankshaft drives a group of gears (front gear

train) on the front of the engine. The front gear

train provides power for the following components:

camshaft, water pump, oil pump, fuel transfer

pump, and accessory items that are specific to the

application.

The cylinder block has seven main bearings that

support the crankshaft. The cyl, inder block uses two

bolts to hold each of the bearing caps to the block.

The crankcase uses a lip seal at both ends of the

crankshaft.

This document has been printed from SPI². Not for Resale

![]()

KENR6231

19

Systems Operation Section

NOTICE

When boost starting an engine, the instructions in Op-

eration and Maintenance Manual, “Engine Starting”

should be followed in order to properly start the en-

gine.

This engine is equipped with a 24 volt starting system.

Only equal voltage for boost starting should be used.

The use of a higher voltage will damage the electrical

system.

The Electronic Control Module (ECM) must be dis-

connected at the “J1/P1” and “J2/P2” locations before

welding on the vehicle.

The engine has several input components which are

electronic. These components require an operating

voltage.

Unlike many electronic systems of the past, this

engine is tolerant to common external sources of

electrical noise. Buzzers that use electrical energy

can cause disruptions in the power supply. If buzzers

are used anywhere on the machine, the engine

electronics should be powered directly from the

battery system through a dedicated relay. The engine

electronics should not be powered through a common

power bus with other keyswitch activated devices.

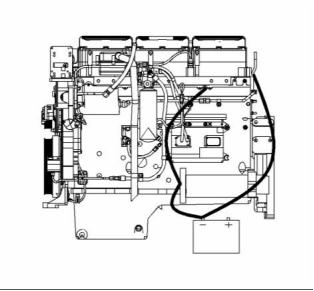

g01028488

Illustration 17

Typical example

Grounding Stud To Battery Ground (“-”)

Engine Electrical System

The electrical system has the following separate

circuits:

• Charging

• Starting (If equipped)

• Accessories with low amperage

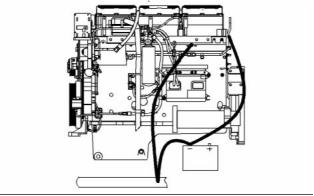

g01028479

Illustration 18

Typical example

Alternate Grounding Stud To Battery Ground (“-”)

The charging circuit is in operation when the engine

is running. An alternator makes electricity for the

charging circuit. A voltage regulator in the circuit

controls the electrical output in order to keep the

battery at full charge.

The engine must have a wire ground to the battery.

Ground wires or ground straps should be combined

at ground studs that are only for ground use. All of

the grounds should be tight and free of corrosion.

The starting circuit is activated only when the start

switch is activated.

All of the ground paths must be capable of carrying

any likely current faults. An AWG #0 or larger wire is

recommended for the grounding strap to the cylinder

head.

Charging System Components

Alternator

The engine alternator should be battery ground

with a wire size that is capable of managing the full

charging current of the alternator.

The alternator is driven by a belt from the crankshaft

pulley. This alternator is a three-phase, self-rectifying

charging unit, and the regulator is part of the

alternator.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

20

KENR6231

Systems Operation Section

The alternator design has no need for slip rings

and the only part that has movement is the rotor

assembly. All conductors that carry current are

stationary. The following conductors are in the circuit:

• Field winding

• Stator windings

• Six rectifying diodes

• Regulator circuit components

The rotor assembly has many magnetic poles that

look like fingers with air space between each of the

opposite poles. The poles have residual magnetism.

The residual magnetism produces a small magnetic

field between the poles. As the rotor assembly

begins to turn between the field winding and the

stator windings, a small amount of alternating current

(AC) is produced. The AC current is produced in the

stator windings from the small magnetic field. The

AC current is changed to direct current (DC) when

the AC current passes through the diodes of the

rectifier bridge. The current is used for the following

applications:

g00425518

Illustration 19

Typical alternator components

(1) Regulator

(2) Roller bearing

(3) Stator winding

(4) Ball bearing

(5) Rectifier bridge

(6) Field winding

(7) Rotor assembly

(8) Fan

Starting System Components

• Charging the battery

Starting Solenoid

• Supplying the accessory circuit that has the low

amperage

• Strengthening the magnetic field

The first two applications use the majority of the

current. As the DC current increases through the

field windings, the strength of the magnetic field is

increased. As the magnetic field becomes stronger,

more AC current is produced in the stator windings.

The increased speed of the rotor assembly also

increases the current and voltage output of the

alternator.

The voltage regulator is a solid-state electronic

switch. The voltage regulator senses the voltage in

the system. The voltage regulator switches ON and

OFF many times per second in order to control the

field current for the alternator. The alternator uses

the field current in order to generate the required

voltage output.

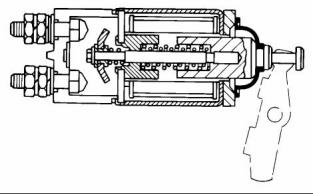

g00317613

Illustration 20

Typical starting solenoid

NOTICE

Never operate the alternator without the battery in the

circuit. Making or breaking an alternator connection

with heavy load on the circuit can cause damage to

the regulator.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

KENR6231

21

Systems Operation Section

When two sets of solenoid windings are used, the

windings are called the hold-in winding and the

pull-in winding. Both sets of windings have the same

number of turns around the cylinder, but the pull-in

winding uses a wire with a larger diameter. The wire

with a larger diameter produces a greater magnetic

field (1). When the start switch is closed, part of the

current flows from the battery through the hold-in

windings. The rest of the current flows through the

pull-in windings to the motor terminal. The current

then flows through the motor to ground. Solenoid

(2)is fully activated when the connection across the

battery and the motor terminal is complete. When

solenoid (2) is fully activated, the current is shut

off through the pull-in windings. At this point, only

the smaller hold-in windings are in operation. The

hold-in windings operate for the duration of time that

is required in order to start the engine. Solenoid (2)

will now draw less current from the battery, and the

heat that is generated by solenoid (2) will be kept at

an acceptable level.

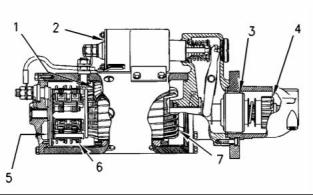

g00425521

Illustration 21

Typical starting motor components

(1) Field

(2) Solenoid

(3) Clutch

(4) Pinion

(5) Commutator

(6) Brush assembly

(7) Armature

The starting solenoid (2) is an electromagnetic switch

that performs the following basic operations:

• The starting solenoid (2) closes the high current

starting motor circuit with a low current start switch

circuit.

• The starting solenoid (2) engages the pinion of the

starting motor (4) with the ring gear.

Solenoid (2) has windings (one or two sets) around

a hollow cylinder. A plunger that is spring loaded is

inside the cylinder. The plunger can move forward

and backward. When the start switch is closed and

electricity is sent through the windings, a magnetic

field (1) is made. The magnetic field (1) pulls the

plunger forward in the cylinder. This moves the shift

lever in order to engage the pinion drive gear with the

ring gear. The front end of the plunger then makes

contact across the battery and motor terminals of

solenoid (2). Next, the starting motor begins to turn

the flywheel of the engine.

When the start switch is opened, current no longer

flows through the windings. The spring now pushes

the plunger back to the original position. At the same

time, the spring moves the pinion gear away from

the flywheel.

This document has been printed from SPI². Not for Resale

![]()

![]()

22

KENR6231

Testing and Adjusting Section

Testing and Adjusting

Section

Testing and Adjusting

i02555248

Belt Tension Chart

Table 1

Required Tools

Tool

Part Number

Part Description

Qty

A

-

Belt Tension Gauge

1

Table 2

Fan Drive Belt Tension Chart

Initial Belt Tension

Gauge Reading

Size of Belt

Width of Belt

(1)

Used Belt Tension

(2)

800 N (180 lb)

5/8

15.875 mm (0.6250 inch)

868 N (195 lb)

Measure the tension of the belt that is farthest from the engine.

(1) Initial Belt Tension refers to a new belt.

(2) Used Belt Tension refers to a belt that has been in operation for 30 minutes or more at the rated speed.

Install Tooling (A) at the center of the longest free

length of belt and check the tension on the belt.

Check and adjust the tension on the tightest belt.

To adjust the belt tension, refer to Disassembly and

Assembly, “Belt Tightener - Install”.

Note: When the belts are replaced, always replace

the belts as a set.

Table 3

Alternator Belt Tension Chart

Gauge Reading

Used Belt Tension

(2)

267 N (60.0243 lb)

Size of Belt

Width of Belt

Initial Belt Tension

(1)

3/8

9.525 mm (0.3750 inch)

400 N (89.9240 lb)

Measure the tension of the belt that is farthest from the engine.

(1) Initial Belt Tension refers to a new belt.

(2) Used Belt Tension refers to a belt that has been in operation for 30 minutes or more at the rated speed.

Install Tooling (A) at the center of the longest free

length of belt and check the tension on the belt.

Check and adjust the tension on the tightest belt.

To adjust the belt tension, refer to Disassembly and

Assembly, “Alternator - Install”.

This document has been printed from SPI². Not for Resale

![]()

KENR6231

23

Testing and Adjusting Section

Fuel System

Fuel System - Inspect

• Relief valves

• Check valves

i02550123

Observe the fuel flow during engine cranking.

Look for air bubbles in the fuel. If there is no fuel

in the sight gauge, prime the fuel system. Refer to

System Operation, Testing and Adjusting, “Fuel

System - Prime” for more information. If the engine

starts, check for air in the fuel at varying engine

speeds. When possible, operate the engine under

the conditions which have been suspect of air in

the fuel.

A problem with the components that send fuel to

the engine can cause low fuel pressure. This can

decrease engine performance.

1. Check the fuel level in the fuel tank. Ensure that

the vent in the fuel cap is not filled with dirt.

2. Check all fuel lines for fuel leakage. The fuel lines

must be free from restrictions and faulty bends.

Verify that the fuel return line is not collapsed.

3. Install a new fuel filter.

4. Cut the old filter open with a suitable filter cutter.

Inspect the filter for excess contamination.

Determine the source of the contamination. Make

the necessary repairs.

5. Service the primary fuel filter (if equipped).

6. Operate the hand priming pump (if equipped).

If excessive resistance is felt, inspect the fuel

pressure regulating valve. If uneven resistance

is felt, test for air in the fuel. Refer to Systems

Operation, Testing and Adjusting, “Air in Fuel -

Test” for more information.

g01096678

Illustration 22

7. Remove any air that may be in the fuel system.

Refer to Systems Operation, Testing and

Adjusting, “Fuel System - Prime”.

(1) A steady stream of small bubbles with a diameter of

approximately 1.60 mm (0.063 inch) is an acceptable amount

of air in the fuel.

(2) Bubbles with a diameter of approximately 6.35 mm (0.250 inch)

are also acceptable if there is two seconds to three seconds

intervals between bubbles.

(3) Excessive air bubbles in the fuel are not acceptable.

i02550146

Air in Fuel - Test

3. If excessive air is seen in the sight gauge in the

fuel return line, install a second sight gauge at the

inlet to the fuel transfer pump. If a second sight

gauge is not available, move the sight gauge from

the fuel return line and install the sight gauge

at the inlet to the fuel transfer pump. Observe

the fuel flow during engine cranking. Look for air

bubbles in the fuel. If the engine starts, check for

air in the fuel at varying engine speeds.

This procedure checks for air in the fuel. This

procedure also assists in finding the source of the air.

1. Examine the fuel system for leaks. Ensure that

the fuel line fittings are properly tightened. Check

the fuel level in the fuel tank. Air can enter the

fuel system on the suction side between the fuel

transfer pump and the fuel tank.

If excessive air is not seen at the inlet to the fuel

transfer pump, the air is entering the system after

the fuel transfer pump. Proceed to Step 6.

2. Install a suitable fuel flow tube with a visual sight

gauge in the fuel return line. When possible, install

the sight gauge in a straight section of the fuel line

that is at least 304.8 mm (12 inches) long. Do not

install the sight gauge near the following devices

that create turbulence:

If excessive air is seen at the inlet to the fuel

transfer pump, air is entering through the suction

side of the fuel system.

• Elbows

This document has been printed from SPI². Not for Resale

400-100-8969???15088860848

0574-26871589? 15267810868

0574-26886646? 15706865167

0574-26871569 18658287286

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文(簡)

中文(簡) Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韓國

韓國 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska